Importance of HVAC Maintenance

Before we dive into the HVAC maintenance checklist, it is important to first discuss why maintenance is important. HVAC systems are one of the largest energy consumers in most commercial buildings at about 25% of total energy use. Couple that with the degradation curves below and you begin to understand that maintenance is a must.

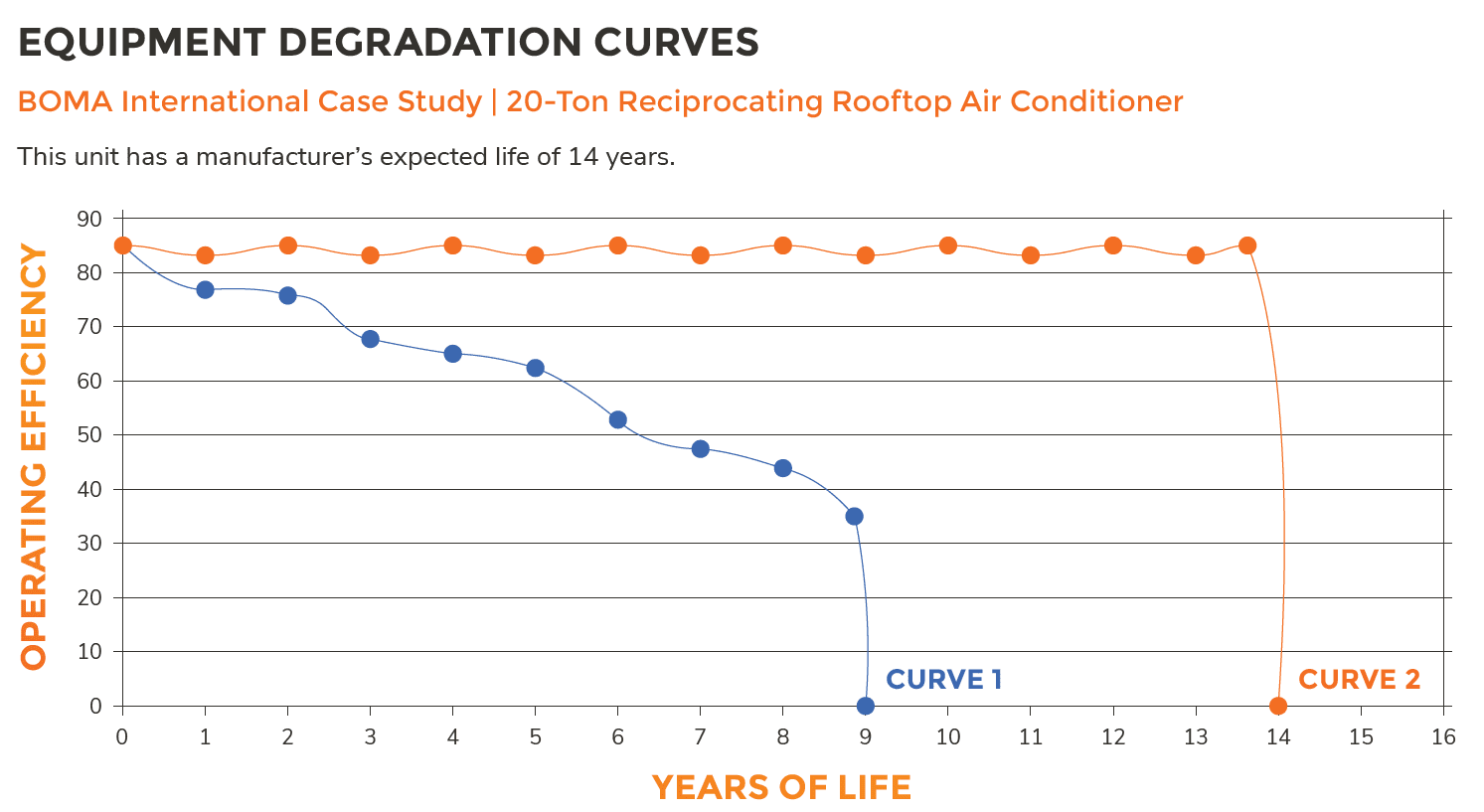

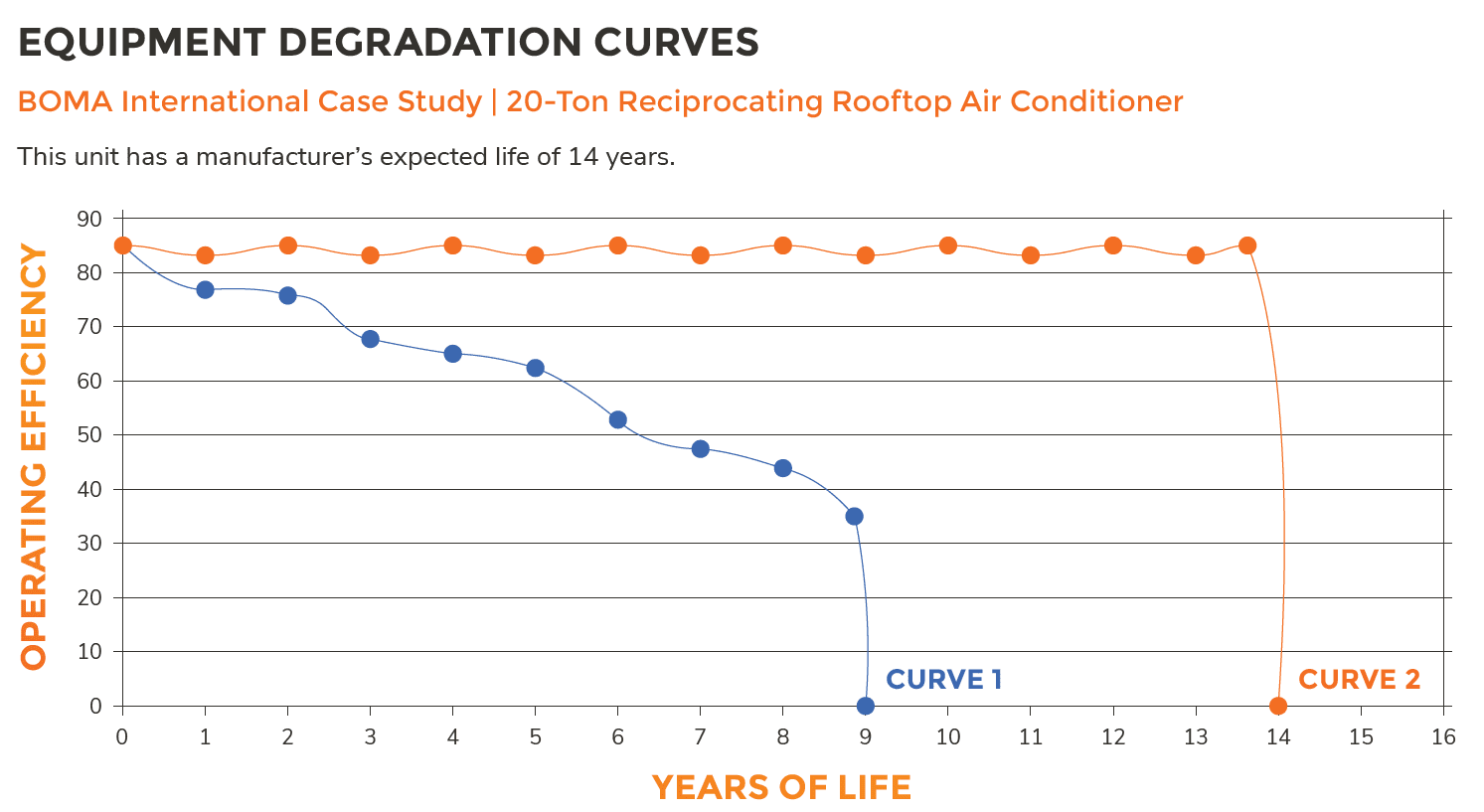

The graph below shows a study done by The Building Owners and Managers Association (BOMA International). This study focuses on a 20-to reciprocating rooftop air conditioner with a 14-year expected life.

As you can see, the poorly maintained unit (Curve 1) resulted in a 9-year life with degrading efficiency (rising energy use and cost) throughout. The well-maintained unit on the other hand (Curve 2) achieved the manufacturers expected life of 14 years, while maintaining a high level of efficiency.

Boma goes on to say that the failure of the well maintained unit was caused by a compressor issue. The compressor was able to be replaced, which leads to an extension of the overall system by another 7 years.

Our HVAC Maintenance Checklist will ensure you buildings HVAC equipment consumes less energy and serves you longer.

HVAC Maintenance Checklist:

The age, condition, location, and type of equipment you have may change the frequency and tasks needed to complete its maintenance. This is a good place start.

The tasks below are to be performed in the spring for cooling systems and in the fall for heating systems. This list contains services which should be performed by a commercial HVAC technician. Maintenance is vital to the longevity of your building’s HVAC systems, helping them run more efficiently throughout the season.

- Coils inspected and cleaned: Cleaning evaporator and condenser coils is easy and effective at keeping your system at peak efficiency.

- Cabinet inspected and cleaned

- Clear drain pans and condensate lines of obstructions: Clogs in your drainage lines can cause moisture to back up into your building. This can cause mold and mildew growth as well as the potential for system damage.

- Measure refrigerant levels and recharged if necessary

- Verify operating temperatures and Superheat and adjust

- Check cap tubes and piping for chafing

- Check hot gas bypass controls

Download Our Printable Checklist Here

- Inspect compressor, measure Amps/Volts

- Inspect and lubricate motor and blades, measure Amps/Volts

- Check control box, switches, wiring and safety controls

- Inspect and replace belts as needed

- Check Sheave alignment, belt tension and lube all bearings

- Tighten motor, bearing, blower mounting bolts

- Clean combustion blower housing

- Clean combustion inlet air screen

- Inspect and clean burner assembly

- Test and clean ignition system

- Test and clean safety controls

- Clean heat exchanger and inspect for soot and leaks

- Check flue system for dislocations and wear

- Tune Combustion with O2 sensor for efficient firing: An improper fuel/air mix will waste fuel and could be dangerous. Have your combustion equipment tuned regularly to save money and prevent production of deadly carbon monoxide.

- Check and tighten control box, wiring and connections

- Inspect dampers, actuators, and linkages for binding, looseness or damage. Lubricate as needed.

- Check duct system for damage or leakage

- Humidifier (if equipped) inspected, cleaned, and operations tested

- Replace or clean Air filter: Inspect air filters every 3 to 4 weeks to ensure the filter has not become clogged. Change air filters every 3 to 6 months, depending on the manufacturer’s recommendation or as needed. Maintenance staff should stay on top of air filter checks and changes. Clean air filters can lower energy consumption by up to 15%.

- Program thermostats: Check the programming on your building’s thermostats to ensure settings are optimal for energy savings. Do this by manually programming your thermostats or through your building automation system.

- Check thermostat operation: If your thermostats are not operating correctly, your HVAC systems could be running more frequently than necessary. If thermostats are not working properly, have them repaired or replaced.

Download Our Printable Checklist Here

Prevent a Breakdown By Carrying These Parts

Below is a list of what you can keep in stock to limit further expenses!

- Air filters

- Belts

- Capacitors

- Coil Condenser Cleaners

- Contactors

- Fuses

- Fan Motor

- Thermostat

- Thermostat Batteries

For larger facilities, it can be cost-effective to build your inventory of more expensive replacement parts. Especially if you have five or more pieces of equipment sharing parts like:

- Motors

- Capacitors

- Gas Valves

- Control Boards

- Compressors

- Bearings

- Shafts

- Impellers, etc.

Many of these items may not be supplied by a local distributor and may have to be shipped by the manufacturer. This can take anywhere from 24 hours to over six weeks before the parts arrive. Keep a few of these items on hand. This provides a cost-saving opportunity because you avoid expedited shipping costs and reduce the possibility of cascading failures.

AC Not Working? Check Out These Symptoms And Solutions.

We Can Help

With proper commercial HVAC maintenance, your building’s heating and cooling systems can operate more efficiently, generating energy savings for your business. At Rasmussen Mechanical Services, we will work with you to create a customized HVAC maintenance plan tailored to the unique needs of your business.