Skid Mounted Compressors

From The Compressed Air Experts

THE COMPRESSED AIR EXPERTS

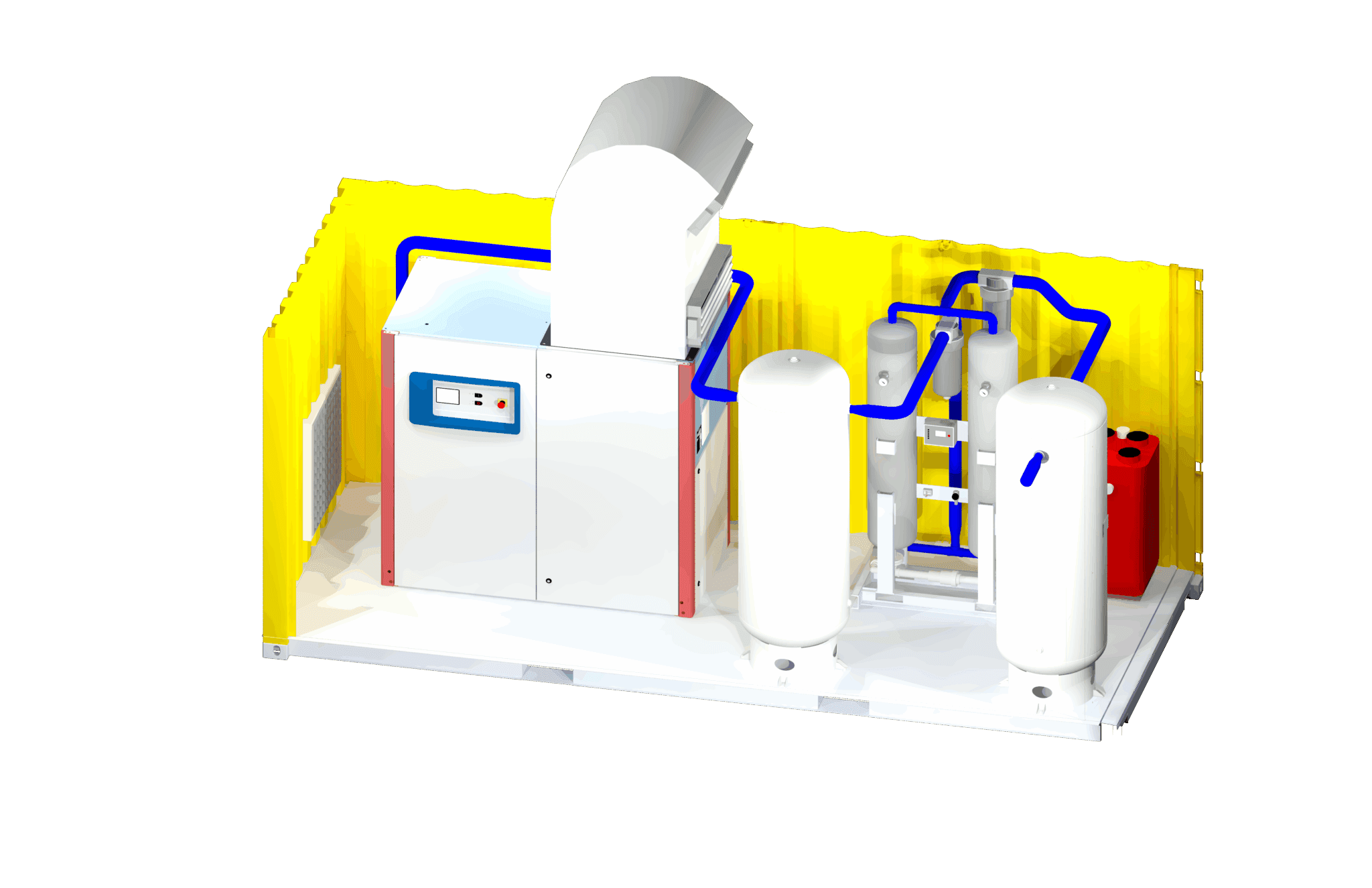

At Rasmussen Mechanical Services, we provide custom-engineered skid mounted compressor systems designed to meet the demanding needs of industrial plants. Our systems can integrate multiple compressors, air dryers, wet and dry air receivers into a single, compact and transportable unit. These turney compressed air systems also include all necessary piping and controls.

These pre-assembled, plug-and-play systems save you time and money on integration by coming fully pre-piped and pre-wired for single-point electrical hook-up. Built on rigid bases with forklift pockets and sling rings, our skid-mounted compressors are easy to transport and engineered for durability in harsh industrial environments.

They also require little to no onsite assembly, making commissioning and startup fast, simple, and cost-effective. Plus, with custom configurations available, we can design a system to match your exact compressed air requirements, from high-pressure applications to oil-free air needs.

WHAT ARE SKID MOUNTED COMPRESSORS

A skid-mounted compressor system is a self-contained, pre-assembled unit that includes everything necessary for efficient compressed air production and management. These systems come pre-piped and pre-wired on a structural steel skid.

BENEFITS OF SKID MOUNTED COMPRESSORS

Plug-and-Play Installation – Minimal on-site assembly and reduced downtime.

Custom-Engineered Solutions – Designed to match your air demand and operational requirements.

Reliable Performance – Includes air dryers and receivers to maintain consistent pressure and air quality.

Scalable & Flexible – Easily expandable to accommodate growing air demand.

CUSTOM SKID MOUNTED COMPRESSOR SYSTEMS

We build skid-mounted compressor systems tailored to your specific requirements. Our solutions include:

Single & Multi-Unit Compressor Packages – Including rotary screw, reciprocating, and centrifugal compressors.

Integrated Air Treatment – High-efficiency air dryers (refrigerated or desiccant) to remove moisture and prevent contamination.

Wet & Dry Air Receivers – For optimized air storage and consistent pressure control.

Custom Controls & Monitoring – Advanced automation, remote monitoring, and pressure management.

Oil-Free & Oil-Lubricated Systems – Options to match your industry’s needs, including food and beverage, pharmaceuticals, and manufacturing.

CALL THE EXPERTS TODAY

TECHNICAL INFORMATION

Skid-Mounted Compressor System Components:

Compressors: Rotary screw, reciprocating, or centrifugal

Air Dryers: Refrigerated or desiccant

Filtration: High-efficiency particulate, oil coalescing, and carbon filters

Air Receivers: Wet and dry storage tanks to manage pressure fluctuations

Drain Systems: Automatic and zero-loss condensate drains

Piping & Manifolds: Pre-fabricated, leak-free stainless steel or aluminum piping

Control Panels: PLC-based controls with remote monitoring capabilities

Power Requirements: 208V, 230V, 460V, or 575V options available

industrial air services brochure

Eliminate Waste and Optimize Your Industrial air systems