LIMPSFIELD BURNERS

Mechanical Equipment & Service Providers

At Rasmussen Mechanical Services, we are proud representatives of Limpsfield burners —a global leader in high-efficiency, low-emission combustion technology. These burners deliver performance and reliability across a wide range of applications. Whether you’re looking to install, service, or upgrade your boiler system, our team ensures your equipment operates at peak efficiency.

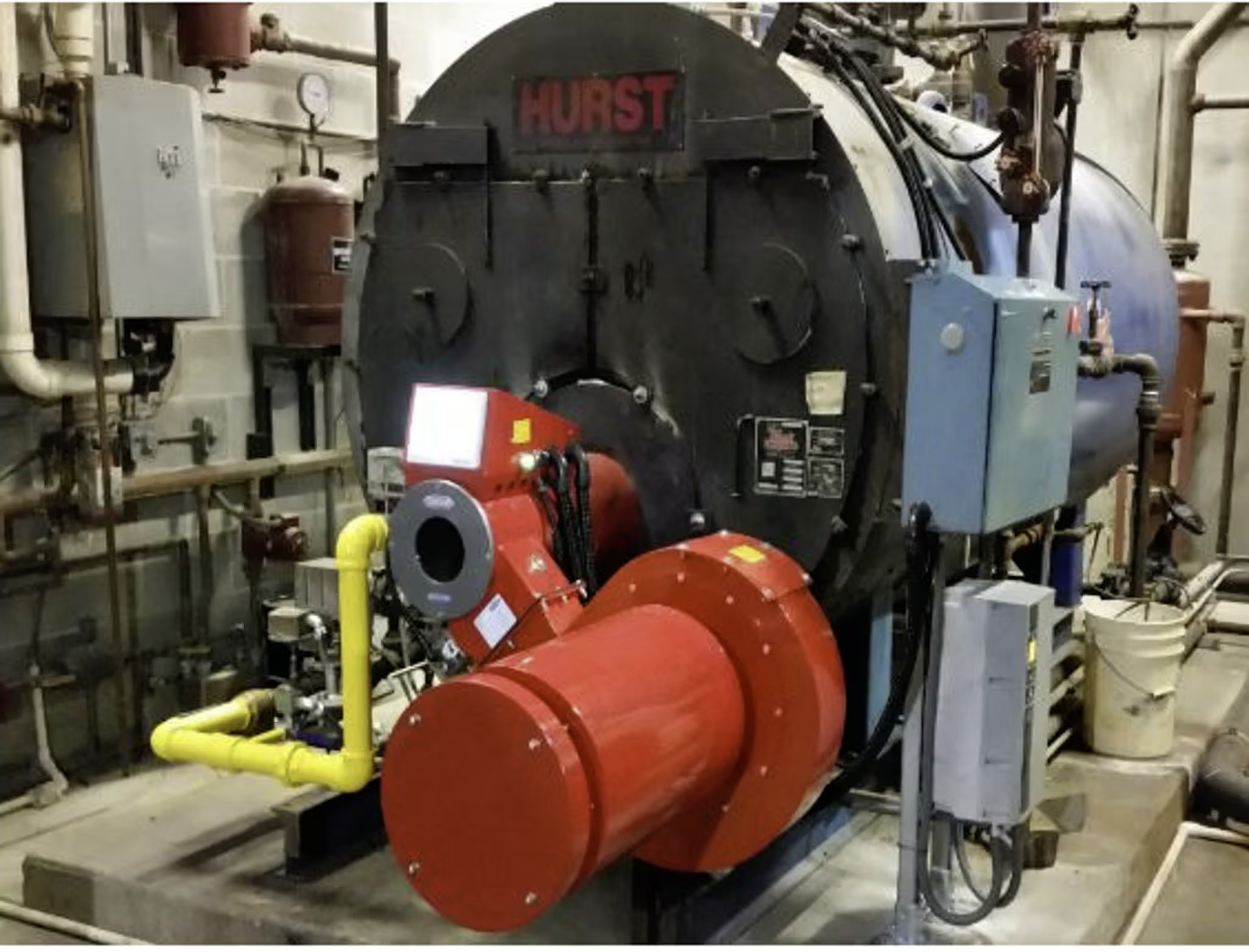

WHAT ARE LIMPSFIELD BURNERS

They are state-of-the-art combustion systems designed to achieve the highest efficiency and the lowest emissions. Known for their precision engineering, these burners are widely used across industries such as manufacturing, food processing, power generation, and oil refining.

WHY CHOOSE LIMPSFIELD

Limpsfield burners have been redefining the boiler industry since their inception in 1995. These burners are the ideal solution for industrial and commercial applications. Here’s what sets Limpsfield apart:

Unmatched Efficiency: Designed to operate at 3% O₂ across the entire firing range, ensuring maximum efficiency and minimal fuel wastage. Maintaining this level of precision prevents heat loss, enhances combustion, and reduces operating costs.

Ultra-Low Emissions: These burners produce virtually 0 ppm CO emissions. They can meet low-NOx requirements as low as 20-30 ppm, making them an eco-friendly choice.

Fuel Flexibility: Capable of running on a wide range of fuels. This includes natural gas, #2 oil, heavy fuel oil, hydrogen, biogas, landfill gas, animal fats, and fish oils. Limpsfield has been a pioneer in burning hydrogen, with installations operating for over 20 years.

Broad Capacity Range: From the compact LP series (750,000 to 10 million BTUs) to the LC series for larger systems (up to 220 million BTUs).

EFFICIENCY AND COMBUSTION

Pre-Mixed Combustion: 85% of air and fuel are mixed before combustion, resulting in a clean, stable flame with consistent performance.

Retention Head Design: The flame is precisely controlled at the burner head, eliminating inefficiencies and minimizing refractory requirements.

Advanced Fuel Control Systems

OIL CONTROL

These burners feature a hydraulically operated oil control system that eliminates after-burn for optimal performance. This system includes:

Hydraulic Shut-Off Valve: Operated at 25 bar supply pressure, the piston-controlled valve ensures precise closure directly at the oil nozzle outlet.

High-Alloyed Steel Nozzles: Designed to handle variable oil quality, these nozzles offer superior combustion and durability.

Spillback Oil Valve: Regulates the amount of oil supplied via a return line, maintaining consistent and efficient oil delivery.

GAS CONTROL

Gaseous fuel is injected at high velocity into the air stream prior to the stainless-steel mixing diffuser. Key features include:

Linkageless Design: A precision-made flange butterfly valve enables one positioning motor to control both fuels.

Gas Control Trains: Manufactured by Limpsfield, these systems include pilot control trains, double block control valves, regulators, and isolation valves. Optional equipment includes:

These advanced systems ensure precise fuel control for consistent performance and seamless operation.

SCHEDULE YOUR SERVICE TODAY!

GET THE HELP YOU NEED FOR ALL THINGS MECHANICAL