Download Brochure

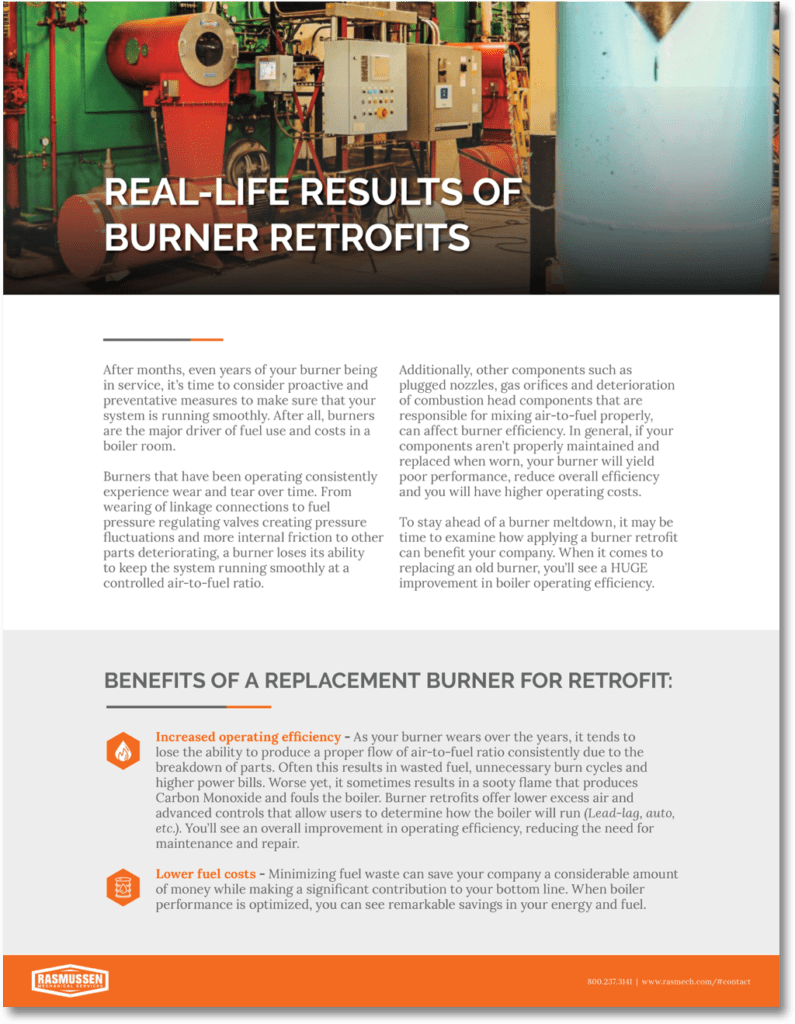

Burners that have been operating consistently experience wear and tear over time. From wearing of linkage connections to fuel pressure regulating valves creating pressure fluctuations and more internal friction to other parts deteriorating, a burner loses its ability to keep the system running smoothly at a controlled air-to-fuel ratio.

In general, if your components aren’t properly maintained and replaced when worn, your burner will yield poor performance, reduce overall efficiency and you will have higher operating costs.

To stay ahead of a burner meltdown, you need to examine how applying a burner retrofit can benefit your system. When it comes to replacing an old burner, you’ll see a HUGE improvement in boiler operating efficiency.

What's Inside

- How retrofits increase operating efficiency

- How retrofits lower fuel costs

- How retrofits increase safety

- How retrofits prove to be a worthy investment

Consistent service maintains your burner’s efficiency, reliability, and most of all, safety. Learn how @RasMech can help. Click To Tweet

ABOUT US

Rasmussen Mechanical Services is an industry leader; a full-service, one-stop-shop for all things mechanical services. With 10 departments, 7 locations, and over 200 employees, Rasmussen Mechanical has wide-ranging expertise in commercial, industrial, and institutional mechanical equipment. We are proud to be a preferred mechanical service company in Industrial Air Services, Boiler Repair, Industrial Burner Services, Mechanical Construction, HVAC, Rental Equipment and more!