When thinking about where you can improve operational efficiency, facility managers rarely thinks of cooling towers. This however, can be a hugely inefficient part of your operation. Cooling towers commonly get out of balance over time and can even be installed that way in some cases.

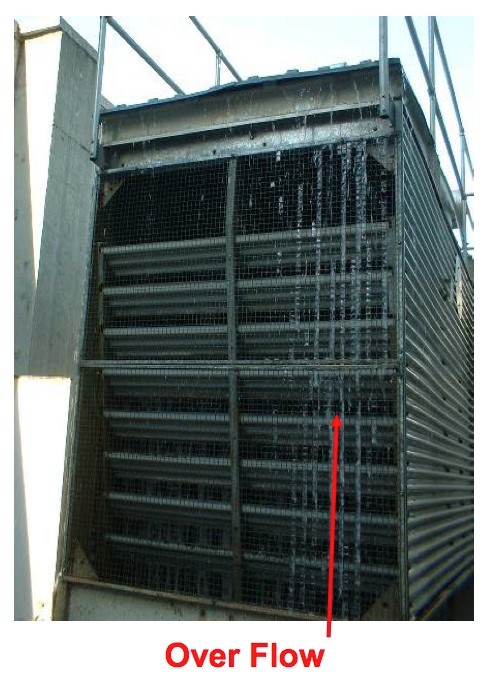

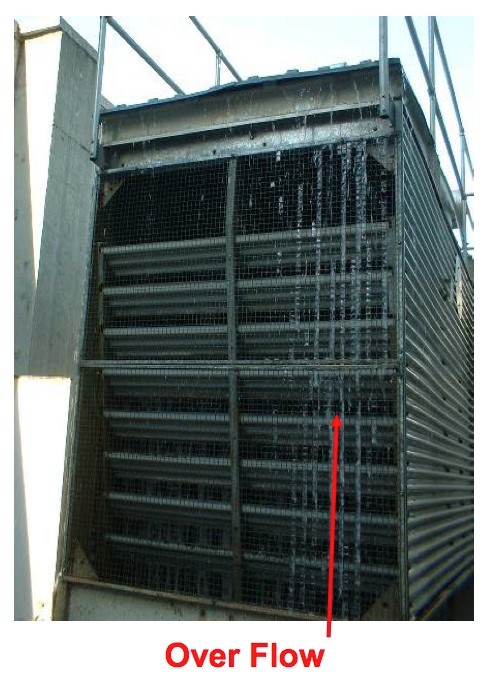

We have encouraged a number facilities to let us examine the flow rates on their cooling towers units to see if we can improve overall efficiency. Fortunately and unfortunately for facilities, we have a high success rate at finding issues. We often find some zones are overflowing, some zones are under flowing and airside velocities are all out-of-whack. This results in units that get nowhere near nameplate performance!

For organizations like ethanol plants and other industrial facilities where summer production is limited by cooling tower output, this can be a huge problem. By re-balancing flows to cooling towers, they will not only increase unit efficiency, but also production capabilities.

In large commercial buildings, inefficiencies in cooling tower performance result in increases in cooling bills. This means small tweaks and improvements can result in BIG savings on energy bills.

Cooling Tower Water Flow

To measure the water flow data, you have to start by using an ultrasonic flow meter. Ultrasonic flow meters work by transmitting ultrasound between two sensors. The two sensors are offset on the pipe carrying the water and measure the time it takes for sound to travel between them. That is how flow speed is determined. From there you can adjust the flow to meet the requirements of the entire system.

“We recently ran into an issue where our technician was having trouble with a motor over amping on a new unit. We brought in our balancing team to help diagnosis the issue and found that the motor was open on both ends. This does not allow the motor to create the pressure it needs and causes the system to pump excess air. We were able to adjust the damper in such a way that the pump could create pressure and reduce air in the system. This change reduced the amperage, which will lower electrical costs and make the unit run more efficiently.” – HVAC Team

While you may be shocked that a new factory unit would be set up to over amp, this is not uncommon. In fact, we see this in the field all the time! When you’re looking to increase efficiency, cooling tower flow rates are a surprisingly good place to start. We also recommend checking flow rates on any main unit AHU, pumps, cooling towers or chillers on a yearly basis. This will ensure you are getting the performance your unit is designed to achieve.

We Can Help

Never had flow rates tested on your equipment? Curious about how efficiently your cooling tower is running? We can help with that. Reach out for a free estimate, call us at 1-800-237-3141 or chat with an agent.