Steam coils (or steam distribution coils) are in use across the world to transfer heat in facilities and in processes applications. Steam coils can be made from aluminum, stainless steel, copper, steel or a number of other combinations. Education facilities, hospitals, offices, apartments, manufacturing facilities and more use these coils to transfer heat. The first step in steam coil replacement is understanding which type of coil you have.

Coil Types

Below are some common types of coils. There are a number of additional types of coils on the market. To read more on additional coil types, check out this article.

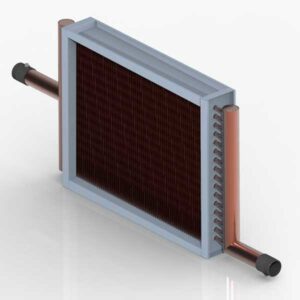

Example of An “S” or “V” Coil

“S” and “V” Coils

These coils have a similar design with straight steam paths and supply and condensate headers on opposite ends of the coils. The only difference between “S” and “V” coils is the diameter of the tubes. When temperatures are above 35 degrees Fahrenheit, these are the appropriate coils.

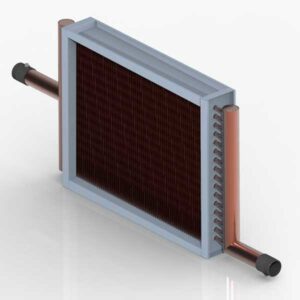

Example Of Supply and Condensate Headers On The Same End Of A Steam Coil

“C” Type Coils

The “C” type coil (or centifeed coil) are used when air temperatures go below 35 degrees Fahrenheit. These are sometimes referred to as “freeze proof coils” because they can withstand colder temperatures. They have supply and condensate headers on the same end. In an article written by Armstrong they describe a “C” type coil as:

“A centifeed coil is one plain tube—called the inner steam distribution tube—inserted inside an outer finned tube. The center tube is fed with steam, which travels up this distribution tube and is then discharged into the outer tube. It then travels back between the outside wall of the distribution tube and the inside wall of the finned tube to the condensate header. The inner tube acts as a steam tracer to keep the finned tube warm along its total length.”

“T” and “P” Coils

Both of these coils are multi pass. When a single pass will not achieve the desired temperature these are the appropriate coils. T type coils have supply and condensate headers on opposite ends of the coils. P Type coils in contrasts, have supply and condensate headers on the same sides of the coil.

Steam Coil Replacement

So how do you size up a coil when you need to replace it? Emergent Coils recommends you do the following:

Additional measurements you will need:

- Number of fins per inch

- Number of feeds coming off each manifold

- Casing depth

- Number of rows of tubing

Armed with this information you should be able to find a steam coil replacement. Also consider whether the coil you are replacing has an AHRI certification. The certification ratings include:

- Average total cooling or heating capacity, Btu/h [W]

- Air pressure drop through coil at standard air density, in H2O [kPa]

- Water, aqueous ethylene or propylene glycol solutions pressure drop through coil (including headers) at average fluid density, ft of fluid [m of fluid]

Steam Coil Failure

Steam coils can fail for a number of reasons but there are 3 common reasons:

- Corrosion from gasses inside the coils.

- Erosion from internal steam velocity or poor steam quality.

- Icing up of condensate in before it leaves the coil.

Regardless of why your coil fails, it is a good idea to have it evaluated by a professional. Reach out to our expert technicians at 1-800-237-3121 or schedule an appointment. We would be happy to help you with all of your steam coil needs.