A plant shutdown, also known as a turnaround, isn’t the most popular activity for companies or employees. In the short term for example, the company loses production time and incurs the cost of third-party contractors. Additionally, the unpredictable costs of newly discovered issues that may be exposed during a shutdown.

Shutdowns allow for the internal components of equipment to be inspected, which is impossible while it is running. Under those circumstances, the ultimate goal is to make repairs and maintain the equipment. In effect keeping your plant running efficiently until the next plant shutdown.

As we partner with many plants to plan and execute their shutdown, we find many approaches. Next are some tips from our best experiences that have helped our customers save time and money during their shutdowns.

Tips to Save Time During a Plant Shutdown:

1. Prioritize time-critical activities with a list.

To begin with, use past documentation/experiences to help you apply a duration for each repair. Then analyze where/why overruns occurred and what you can do to avoid them this time.

Below are the systems and equipment that need to be serviced in order for your plant to run efficiently until your next plant shutdown:

- The equipment/system needing service.

- The scope of work for the repairs/maintenance.

- It’s priority rank, 1 being the most crucial and 100 being the least.

- Include the trades needing access to the equipment/system. Can they work at the same time? What order will they need access to?

- Do you have a lockout plan? Who locks this equipment out?

2. Prioritize access.

Presently, many contractors work together and need access to the same piece of equipment and system. When the goal is to save time and decrease costs, identify which contractors get access to the equipment first. For example, for each piece of equipment or system, list the contractors needing access and what their priority is. Another key point is to consider a pre-shutdown coordination meeting or call including all contractors working on critical equipment.

Henceforth, use this as a guideline to create your shutdown schedule. Before inspections create contingency plans that are ready to go if issues are found. Have your list of lower priority items for contractors that complete scope ahead of schedule. Also if you brought in the materials ahead of time, some items that didn’t make the cut may still be completed.

3. Cater lunch/dinner.

It’s important to realize that we’re not just saying that because people like free food. By having food on site ready to eat, you can get trades back to work within 30 minutes.

4. Provide a “resource package.”

Like wedding invitations, the purpose of this resource package is to get people to show up at the right time with the right gear. Within this package you should:

- List the hotels in the area – Keep in mind that you’re most familiar with your area. By making sure everyone is as close to the site as possible you will save time. You can also save money by working with hotels to get a reduced rate.

- List safety requirements – Provide a list of all the safety training requirements for your site.

- Provide a schedule of work ahead of time.

- Have a map of your site:

-

-

- List parking areas

- Smoking areas

- Cell phone areas

- Contractor staging areas

- Exit plans

-

Plant Shutdown Tips to Save Money:

1. EQUIPMENT/SYSTEM WORK ORDERS.

Firstly, provide a list of work orders ahead of time to all of your contractors. These work orders should be associated with all the equipment or systems the contractor is repairing or servicing. While also including instructions for tracking and charging time to the work order too.

2. NEGOTIATED RATES.

Work with your trusted partners in order to negotiate rates for your shutdown. The contractor gets the added benefit of guaranteed work. And subsequently you get the savings through a reduced rate.

3. PROVIDE ONSITE SERVICES.

- Safety: Use your own or contracted safety teams to work as a hole watch and fire watch. This reduces costs because you are freeing up the tradesmen to perform work.

-

Having scaffolding set up prior to a shutdown can save time and money.

Scaffold: Consider bringing a scaffold on site. Also have pre-shutdown meetings with major contractors and get their scaffold requirements. Have scaffolding erected prior to the shutdown. (This saves time, too!) Keep a scaffolding crew available for daily inspections, modifications or additional needs. If all contractors are working on lifts or bringing their own scaffold, things can get crowded and dangerous due to faulty equipment. Watch for untagged or non-OSHA approved scaffolding and ensure contractors use scaffold and lifts safely.

- Cranes: Many plants will hire 1 crane if there is a lot of lifting during the shutdown. Plan and schedule lifts before shutdown starts in order to keep everyone on the same page. Bringing in 1 crane prevents each contractor from having to bring in their own. This eliminates the added expense and can reduce the number of people on-site to manage. Rent the crane with a rigger in the hope that, like scaffolding, it will help to ensure the safety of ground personnel. Your plant shutdown may not require cranes. In any shutdown, due to regulations, ensure anyone who is coordinating lifts on site is properly trained. By using the right gear and keeping everyone in the work area safe with proper barricades, you can avoid injuries.

3 Types Of Plant Shutdowns

Planned Shutdown

A planned shutdown is the ideal shutdown. This type of shutdown is carefully planned months in advance. The frequency of planned shutdowns depends on the nature of the manufacturing process and the utilization of the plant. Remember that planned shutdowns are an investment, not simply a cost.

Emergency Shutdown

These are not ideal. Emergency shutdowns occur when something catastrophic has happened and halting production immediately for repairs is the only option. It seems these happen at the worst possible time. Regular maintenance, including the occasional shutdown, decreases the likelihood of needing to do an emergency shutdown.

Partial vs. Full Shutdowns

Not every shutdown requires a full stop in production. Partial shutdown maintenance can be a good way to keep the plant operational in some capacity. Partial shutdowns can be a difficult dance. When a portion of the plant is operating as normal and maintenance is occurring in another part of the plant, miscommunication can be disastrous.

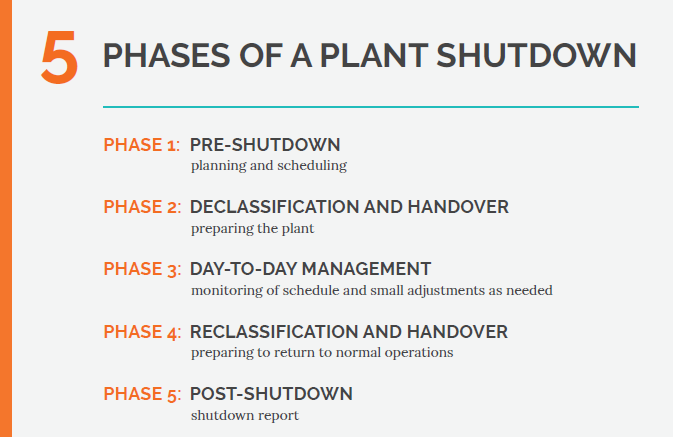

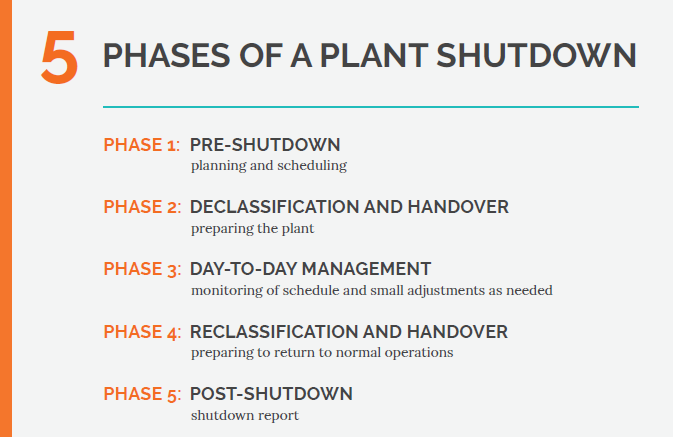

5 Phases of A Plant Shutdown

1. Pre-Shutdown

Gather a team to lead the shutdown. Be sure they include people from several departments. This way you get a complete picture and are less likely to overlook factors that could derail progress during the shutdown.

Who To Include:

- Engineering

- Validation/technical operations

- Manufacturing operations

- QA

- QC

- Procurement

- Safety

- Planning or S&OP team

List all activities that need to be assessed. Under each activity, list:

- Who will perform the activity

- What resources they will need

- How long the task will take

- If there are any dependent tasks

- If this task will directly impact other tasks, like a power supply outage or smoke pattern testing.

1. Send A Notification. Now that you’ve estimated how long each task will take, make a final decision on what dates the shutdown will take place. Then begin to notify the entire plant. Be sure that you include “more information to come” in the message to the entire plant. Don’t feel like this initial message needs to extremely detailed.

2. Nail Down Contracts. Based on the list, generate a master timeline for the shutdown using a Gantt chart. Using the original list and Gantt chart, order necessary equipment and supplies. Next, run competency and risk screening on all third-party contractors. Then nail down contracts. These should be as detailed as possible. Lay out exactly what the contractor is responsible for and get them signed.

3. Ensure Accountability. Dedicate a member of the shutdown leader’s team to each contractor. They will ensure the contractors work is being completed to the degree laid out in their contract and on time. This person will also serve as a point of contact for contractors.

4. Be Prepared For The Unexpected. Create a contingency plan if preferred contractors are not available.

5. Additional Tasks To Accomplish:

- Be sure to also make the Gantt chart available to the contractors.

- Clarify the criteria for handovers between each shutdown task. Determine who will have final approval of what and how.

- Convey that a plant in shutdown is still a GMP (Good Manufacturing Practice) facility, not a building site. Be sure to have proper signage.

- Create a plan to take care of waste. Make sure you have large dumpsters.

2. Declassification and Handover

- Make a detailed list of tasks organized by space or things that need to be done to prepare for the shutdown.

- Prepare the plant by clearing the space where possible. Things that can be moved, should be bagged and tagged. Cover and secure immovable items.

- Open pipes should be sealed and/or capped off to prevent contamination.

- Monitoring points should also be sealed off.

- Walk through the plant with your list to ensure that everything is ready for Phase 3.

3. Day-to-Day Management

- Enforce your plants PPE requirements to ensure safety.

- Restrict access to only those needed.

- A designated member of the Shutdown Leadership Team should work closely with their respective contractor(s) to ensure they are working safely.

- Work should be verified upon competition.

- Create a Daily Change-Control Committee. These individuals will manage alterations to the timeline, or in most cases, do everything they can to maintain the timeline as roadblocks appear. This is crucial to the budget of the shutdown.

- The Daily Change-Control Committee should create a “plan, do, review, and adjust” at the start of each day with all key stakeholders. At the end of the day, the committee should review the timeline and make changes as needed.

- Many significant changes to plant equipment require requalification. Make sure these are done.

- Shutdowns generate a lot of waste. Do not allow this to build up. Clean regularly. This will make getting back to normal productions more efficient.

4. Reclassification and Handover

- Double check verified work.

- Clean the entire plant top to bottom. This step is often rushed or skipped altogether.

- Clean the HVAC system. Contamination is generated during shutdowns. A healthy HVAC system will remove contamination and return the plant to its “at rest” state in about 24 hours.

- Do a visual inspection of the entire plant.

- Formally sign off and hand the plant back to operations.

5. Post-Shutdown

- Confirm that equipment is working as expected.

- Remember that some equipment may have been reset. Make the necessary adjustments.

- Close any remaining change controls and deviation incidents.

- Begin the post-shutdown report. Include:

- Executive Summary : It should be a brief overview of what went well and what didn’t.

- Completed Handover Checklists Covering All Activities

- Engineering Status

- Environmental Controls

- Validation Status : It should all be validated.

- Change Status: It should all be closed.

- Changes to Timeline: It should show why they were needed.

- Environmental Controls

Submit the report for approval to the shutdown leaders, including the plant owner.

3 Other Important Things To Remember

Plant Shutdown Scheduling

Regardless of what type of shutdown is occurring, shutdown management needs to be on top of the operating schedule. This helps to ensure shutdown scheduling doesn’t interfere with other jobs. Detailed planning of shutdown work should also be combined with scheduling to ensure tradespeople and contractors can be included in the planning process. This is especially important for process industries, like power generating stations or ethanol plants that can be operational 24/7.

Plant Shutdown Safety Practices

Ensuring you have enough time during the planning stage of a shutdown is essential. It is also important to focus on industry specific hazard. Chemical plants, ethanol plants, and manufacturing plants often have different hazards. One of the key steps for chemical plants from an article by Craftforce on safety states:

“Some plants, typically chemical, pose a real risk of exposure to toxic chemicals. This might include acidic chemicals, flammable gases, toxic fumes, airborne fibers, and others. Bring on a specialist to test for exposure risk. Also be sure to check out OSHA’s resources on Controlling Exposures if you detect hazards you need to control.”

Why Plant Shutdowns Matter

Ultimately, plant shutdowns give operators the opportunity to fix and prevent issues before they arise and cause, unplanned shutdowns, costly outages or worker injuries. With proper preparation, and using these tips, you can save valuable time and expenses during your future shutdowns.

It is also important to remember that proper documentation can be a lifesaver. This includes lists of shutdown work, the process inventory plan, permits, critical-path schedules and plant shutdown budgets. It should also include all isolation and vessel-entry procedures, as well as contact info and job responsibilities for everyone involved in the shutdown.

Need Help?

If you have any questions or need help with your own shutdown, contact us today! Call the pro’s at Rasmussen Mechanical Services at 1-800-237-3141, email sales@rasmech.com or chat with an agent. Our team is here to help!