The year is finally coming to an end and we think it’s important to look back on some of the lessons learned. We pulled together some of our best real-life examples to help you avoid some expensive mistakes!

1. Leak Testing

Think leak testing your equipment is a waste of time? We beg to differ. In doing a routine leak test we found over 40 leaks checking 15 make up air units! See these pink ties, each one is a leak. The unit pictured in the upper left is a 1 million BTU unit, how much money do you think fixing these leaks will save this facility?

2. Bearing Maintenance

Who spends time maintaining their bearings? While bearings don’t require much attention, one thing you should always do is ensure they have proper lubrication. The type and amount is often dictated by the speed, temperature, load and environment. Follow the manufacturers recommendations and help prevent an exhaust fan bearing failure like we see here.

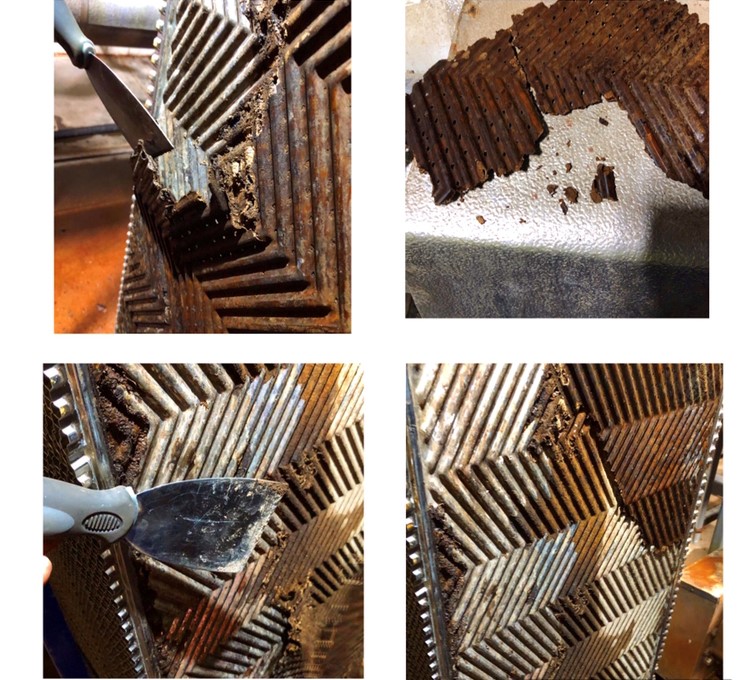

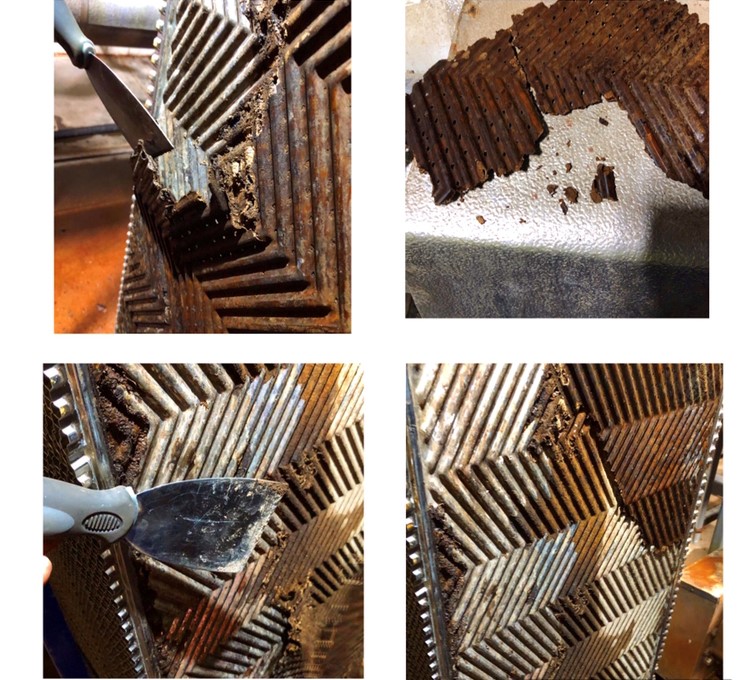

3. Plate and Frame Heat Exchanger Maintenance

Look at the amount of buildup on this hot water heat exchanger.

Build up like this drastically reduces the plate’s ability to transfer heat and increases your operating costs. It can also result in a negative effect on the products you are making. It’s important to monitor the temperature differential of a plate and frame heat exchanger. If it is not within an acceptable range, you should make time to have the plates cleaned. Schedule this during a normal shutdown to avoid costly delays.

Luckily, we were able to remove the debris off the plates and get this unit back online so it can continue to provide heat for a food processing plant.

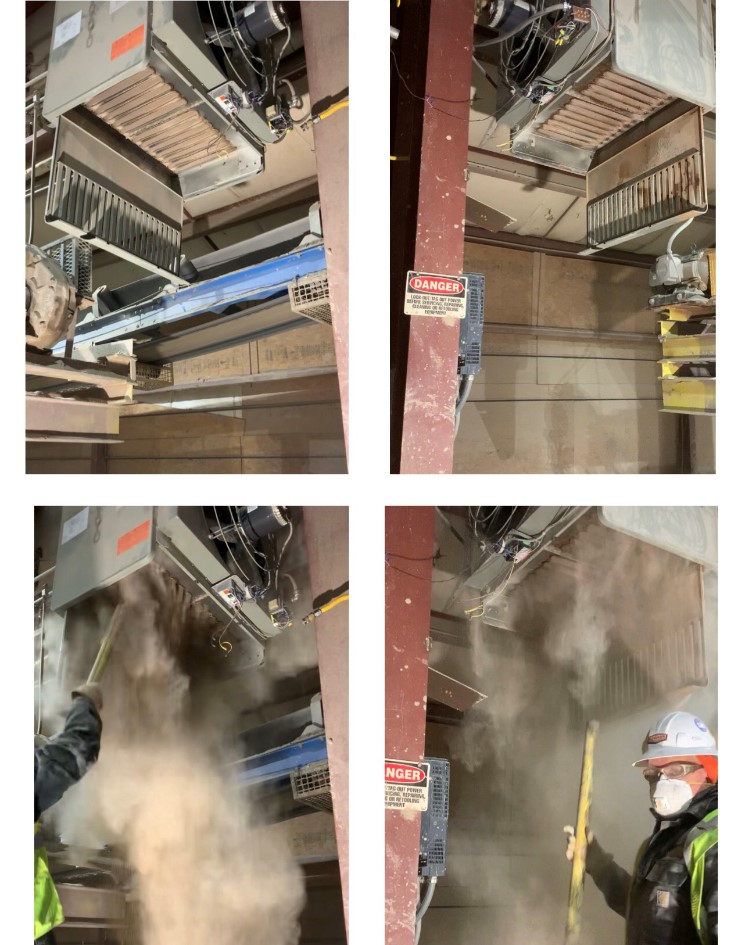

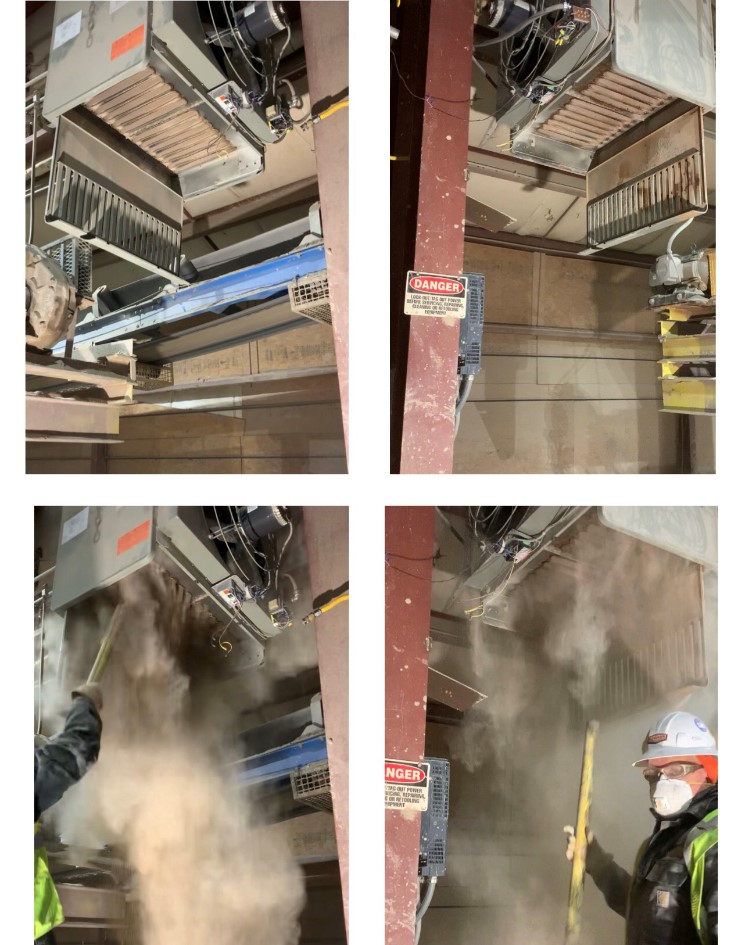

4.Burner Assembly Clean Out

We were performing maintenance at a brick manufacturing plant and ended up uncovering more than just a little build up. A clean burner assembly is an efficient burner assembly. In some cases they are bound to get dirty, but this example emphasizes how the location of HVAC equipment can effect its condition. A unit like this needs to be serviced more frequently than others.

5. Heat Exchanger Cleaning

This boiler almost caused a catastrophic failure at a local country club. The heat exchanger was clogged, and the flames were rolling out of the boiler when we arrived. Luckily, we were able to shutdown the boiler and replace the heat exchanger before anyone was hurt.

A routine cleanout would have helped prevent this situation.

6. Water Treatment

If ever there was a picture to show the importance of treating your boiler feed water, this would be it. Who ordered a mushroom in their boiler? This is an extreme example of what can happens when boiler water treatment is neglected and you have naturally hard water. Poor water treatment = poor performance.

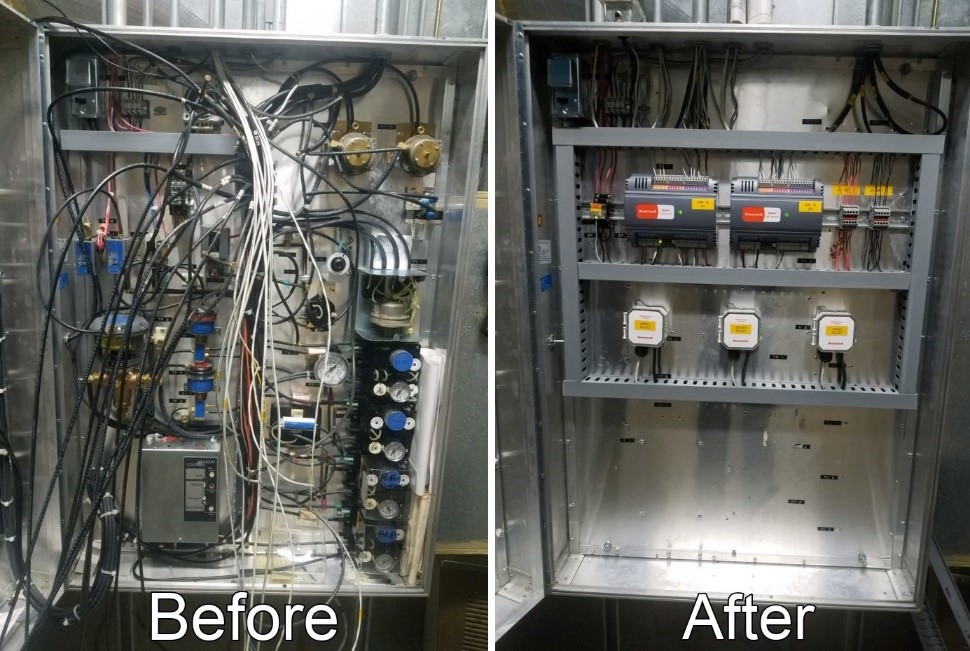

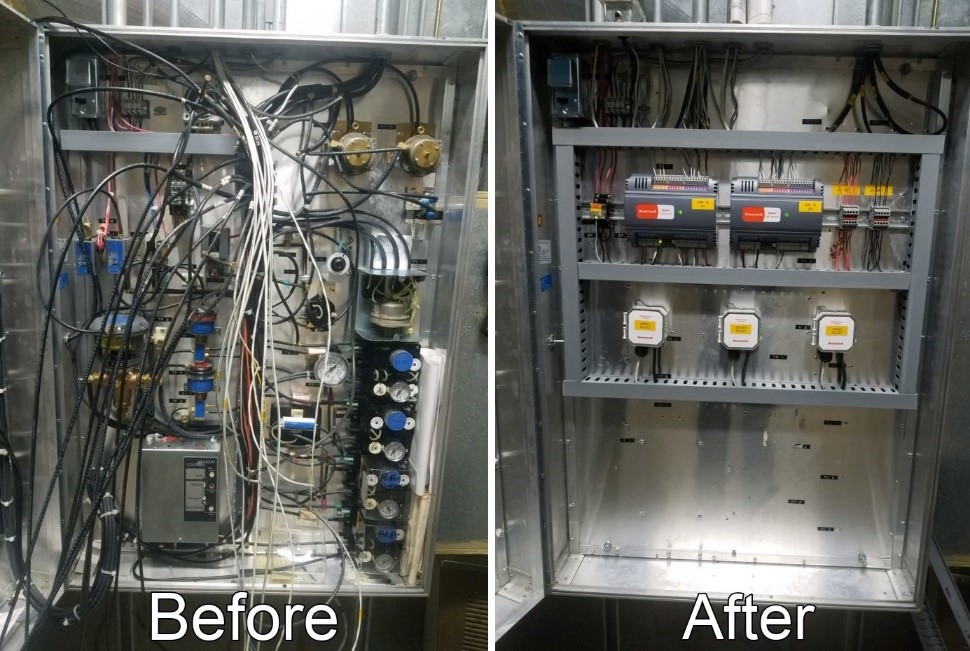

7.Pneumatic Control Upgrades

It was time for an upgrade. Pneumatic controls are costly and can become chaotic. This is what happens when you replace old controls with Honeywell BAS Controls. What a difference!

8.Plant Expansion

This is not a maintenance tip but more of a suggestion. If you need boilers piped for your new building on a hilltop in winter, it is always preferred to have the building up first. RasMech snow removal coming soon!

9. Expansion Joint Replacement

A technicians was working on a Hydronic Boiler when an expansion joint unexpectedly failed. This sent 180-degree water shooting across the room and caused 2nd degree burns down most of his back.

These joints are important to maintain and they have an average life of 3-5 years. The pictures above show breaks in the rubber seal that resulted in the failure. Not only is this bad for whoever is unfortunate enough to be close by when it breaks, but it is also bad for your equipment. Please be sure to inspect your expansion joints for signs of stress and replace them as needed.

Neglecting Your Maintenance?

Together we can learn from these experiences and help prevent unexpected equipment failures and efficiency loss in the future. If you need help with your maintenance reach out! Receive a free estimate, call us at 1-800-237-3141 or chat with an agent.