Flue Gas Analysis Services

Improving Combustion Efficiency, Safety, and Performance

THE COMBUSTION EXPERTS

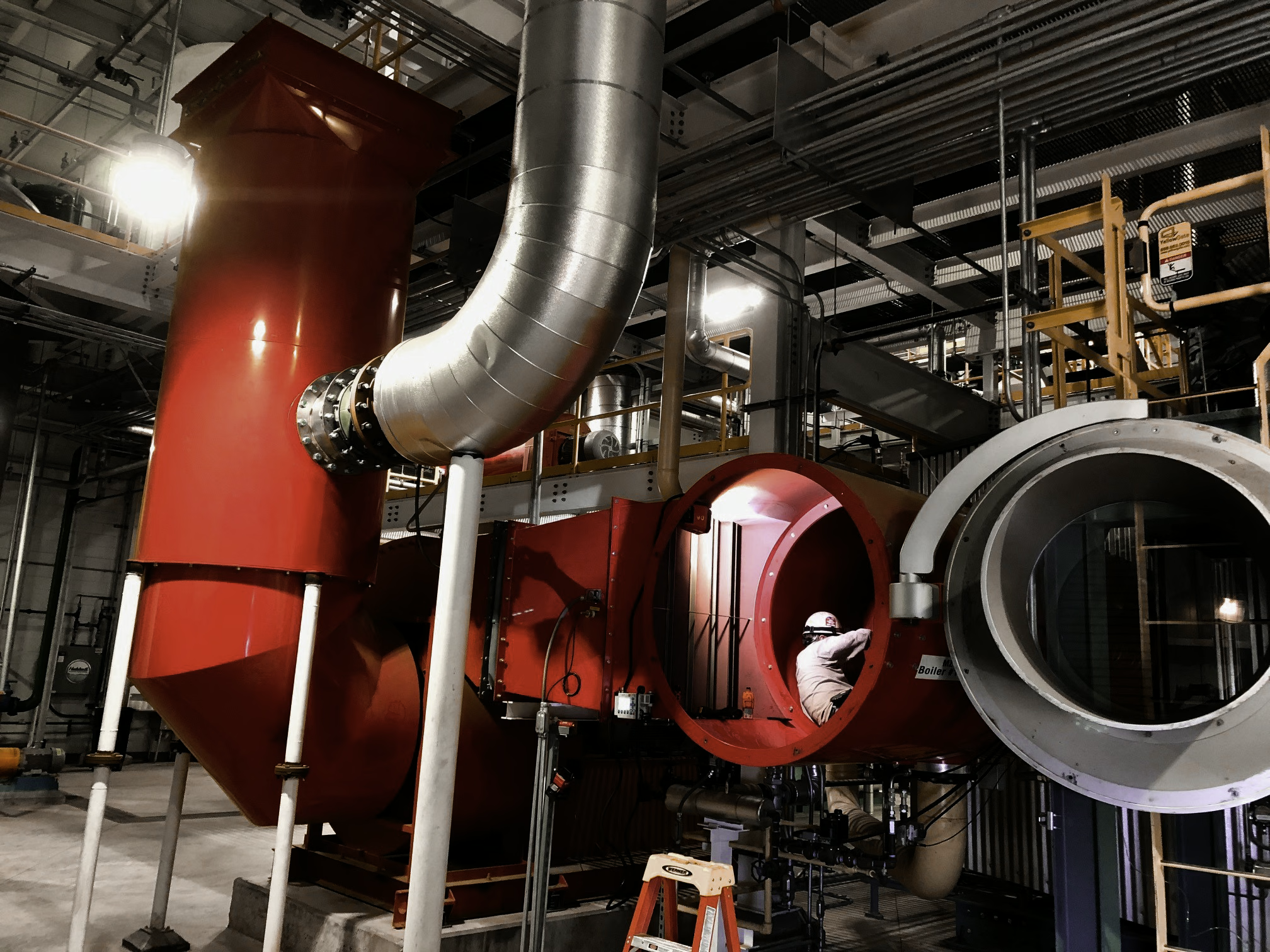

Flue gas analysis is a critical boiler service that directly impacts efficiency, safety, and operating costs. When performed by experienced boiler technicians, flue gas analysis allows precise combustion tuning that reduces fuel waste, lowers emissions, and improves reliability.

Our expert team works on commercial and industrial boiler systems that demand consistent performance, regulatory compliance, and measurable energy savings. Whether your boiler is new, aging, or experiencing rising fuel costs, professional combustion tuning can deliver immediate results.

WHAT IS FLUE GAS ANALYSIS?

Flue gas analysis is the process of measuring combustion byproducts in a boiler’s exhaust stack using a flue gas analyzer. These measurements reveal how effectively fuel and air are being mixed and burned inside the combustion chamber.

A proper flue gas analysis typically measures:

Oxygen (O₂) – Indicates excess air levels

Carbon Dioxide (CO₂) – Reflects combustion efficiency

Carbon Monoxide (CO) – Signals incomplete combustion and safety risks

Stack Temperature – Shows heat loss through exhaust gases

When analyzed together, these data points allow technicians to fine-tune combustion and optimize boiler performance.

WHY CUSTOMERS SCHEDULE FLUE GAS ANALYSIS FOR THEIR BOILERS

Boilers rarely drift out of tune all at once. Instead, efficiency slowly degrades as fuel quality changes, components wear, and operating conditions shift. Without flue gas analysis, these issues often go unnoticed until fuel bills spike or safety concerns arise.

Customers schedule flue gas analysis to:

Lower natural gas or fuel oil consumption

Correct improper fuel-to-air ratios

Reduce carbon monoxide (CO) risk

Improve heat transfer and boiler response

Meet insurance, safety, and code requirements

Extend boiler and burner life

For facilities with high run hours, even small combustion improvements can generate significant annual savings.

WHEN SHOULD YOU SCHEDULE FLUE GAS ANALYSIS?

Flue gas analysis should be performed:

During boiler startup or commissioning

After burner repairs or component replacement

As part of annual preventive maintenance

When fuel usage increases unexpectedly

If combustion-related alarms or issues occur

After seasonal changes for large boilers

Regular testing ensures boilers remain tuned as operating conditions change over time.

SCHEDULE A BOILER FLUE GAS ANALYSIS

If your boiler system has not been evaluated recently, flue gas analysis can provide valuable insight into its current performance. Combustion testing and tuning help ensure the boiler is operating efficiently, safely, and as designed.

Contact a qualified boiler service provider to schedule flue gas analysis and combustion tuning for your boiler system.

WHY CHOOSE A PROFESSIONAL FLUE GAS ANALYSIS SERVICE

Flue gas analysis and combustion tuning should be performed by trained boiler professionals with the proper tools and experience. Improper adjustments can reduce efficiency, create unstable combustion conditions, or introduce serious safety risks. A professional flue gas analysis involves testing with calibrated analyzers, evaluating results through experienced boiler and burner technicians, and making precise fuel and air adjustments to ensure safe, efficient operation. The process also includes clear documentation of combustion performance and recommendations for ongoing optimization as operating conditions change. This work is performed across all major boiler and burner manufacturers, with combustion tuning tailored to the specific equipment and application.

OUR BOILER COMBUSTION TUNING PROCESS USING FLUE GAS ANALYSIS

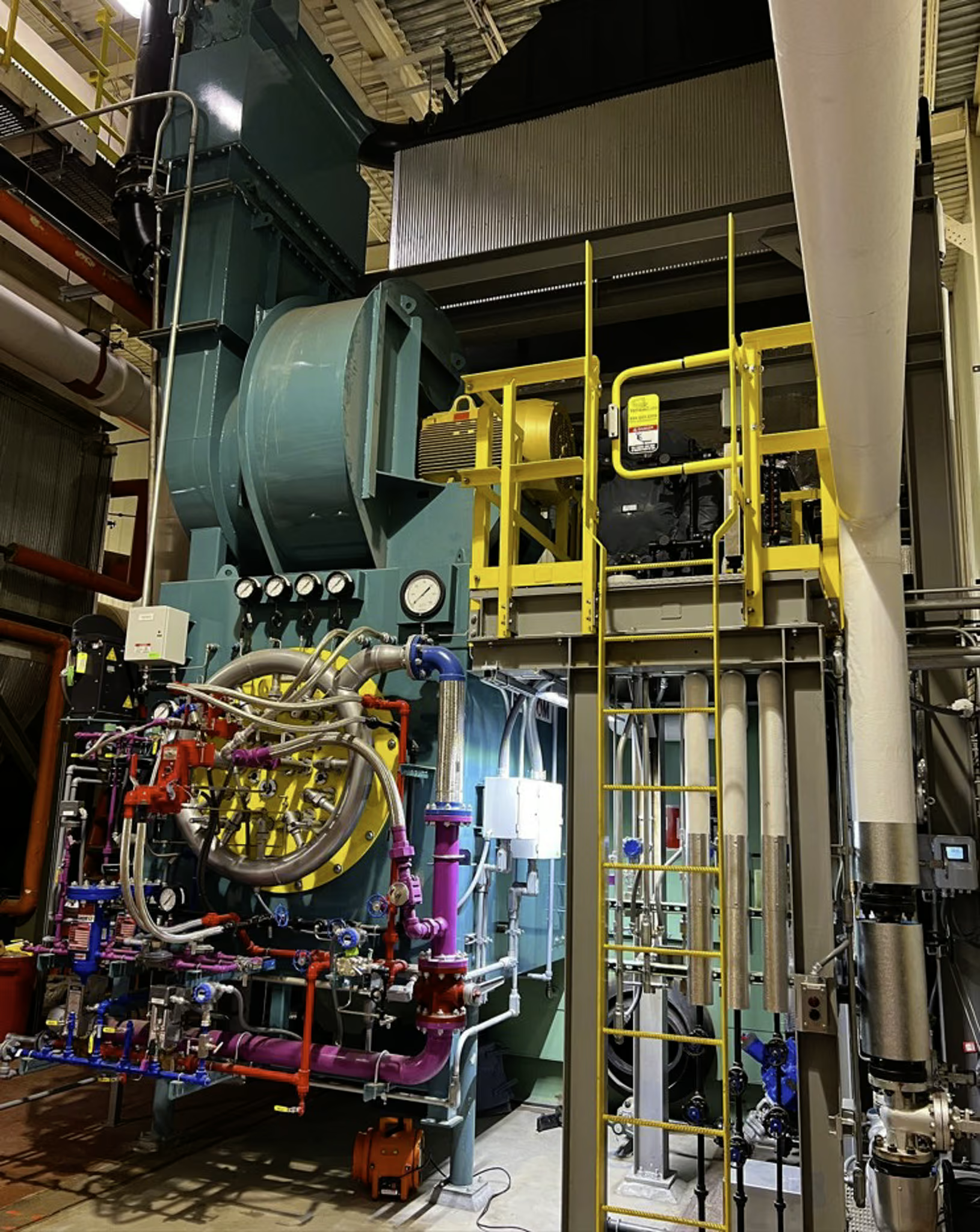

Combustion tuning is the process of adjusting burner settings to achieve the optimal fuel-to-air ratio. Flue gas analysis is the primary tool used to verify and guide these adjustments.

1. Boiler and Burner Inspection

The tuning process begins with a thorough inspection of the boiler, burner, fuel system, and venting. Technicians look for mechanical issues such as leaks, corrosion, damaged components, or airflow restrictions that could affect combustion performance. These issues are addressed before adjustments are made.

2. Combustion Analysis and Measurements

A combustion analyzer is then used to collect baseline data from the flue gas. Key readings include:

Oxygen (O₂) percentage

Carbon dioxide (CO₂) levels

Carbon monoxide (CO) concentration

Stack temperature

These measurements establish how efficiently the boiler is currently operating and where adjustments are needed.

3. Adjusting the Fuel-to-Air Ratio

Using real-time flue gas readings, burner settings are adjusted to achieve the proper balance between fuel and combustion air. Real-time data from flue gas analysis helps operators tune the air-to-fuel ratio for optimal burning, potentially saving 5–15% in fuel costs. It is important to avoid low excess oxygen or low combustibles, as these low levels can indicate incomplete combustion, reduced efficiency, or potential safety hazards. This may involve fine adjustments to air dampers, O2 tim systems, fuel pressure, or burner controls. In large or complex systems, reaching certain measurement points with probes can be challenging, but accurate readings are essential. The goal is to minimize excess air while maintaining stable combustion and safe operating conditions.

4. Performance Testing and Verification

After adjustments are complete, the boiler is tested under operating conditions. A final flue gas analysis confirms:

Acceptable carbon monoxide (CO) levels in the product (flue gases)

Proper oxygen and carbon dioxide readings

Improved combustion efficiency

Stable operation across firing ranges

For perfect performance verification, it is essential to use analyzers that are highly suitable for monitoring combustion in various applications. Zirconium oxide sensors are specifically used for measuring O₂ in high-temperature environments during flue gas analysis.

This final verification ensures the boiler is operating safely, efficiently, and reliably.

SCHEDULE YOUR SERVICE TODAY!

GET THE HELP YOU NEED FOR ALL THINGS MECHANICAL

Flue Gas Analyzer 101

A flue gas analyzer is an essential tool for anyone involved in combustion flue gas analysis, providing real-time feedback on the combustion process within boilers, furnaces, heaters, and other combustion appliances. By measuring the composition of flue gas—specifically gases like carbon monoxide (CO), carbon dioxide (CO₂), oxygen (O₂), nitrogen dioxide (NO₂), and nitric oxide (NO)—these devices help operators ensure that fuel is being burned efficiently and safely.

To perform gas analysis, the operator inserts the analyzer’s probe into the flue, allowing the device to sample the exhaust gases directly from the system. The probe is connected to a hose assembly, which draws the flue gas into the analyzer. Inside, advanced electrochemical sensors detect and measure the concentration of key gases. The results are displayed instantly, giving the operator valuable data on the current state of combustion.

Safety is a top priority when using flue gas analyzers. Detecting dangerous levels of carbon monoxide or other harmful gases allows for immediate corrective action. This can help to prevent health risks and equipment damage. In addition, regular use of a flue gas analyzer supports compliance with safety regulations and environmental standards.

Flue gas analyzers are versatile and can be used across a wide range of applications, from large industrial boilers to smaller commercial heaters and appliances burning natural gas or other fuels. Whether troubleshooting combustion problems, verifying system performance, or conducting routine maintenance, these devices provide the feedback needed to keep combustion systems operating at peak efficiency.

In summary, using a flue gas analyzer is a critical step in maintaining the safety, efficiency, and compliance of any combustion appliance. By following proper procedures, regularly checking and calibrating the device, and responding promptly to the feedback provided, operators can ensure their systems are running safely, efficiently, and in line with all regulatory requirements.