Boiler tuning is the act of adjusting combustion to achieve optimal performance. Proper tuning is crucial to maintain efficiency, reduce emissions, and extend the life of the boiler. In this article, we will discuss the importance of tuning, the factors that affect combustion, and the steps involved in tuning a boiler.

Importance Of Proper Boiler Tuning

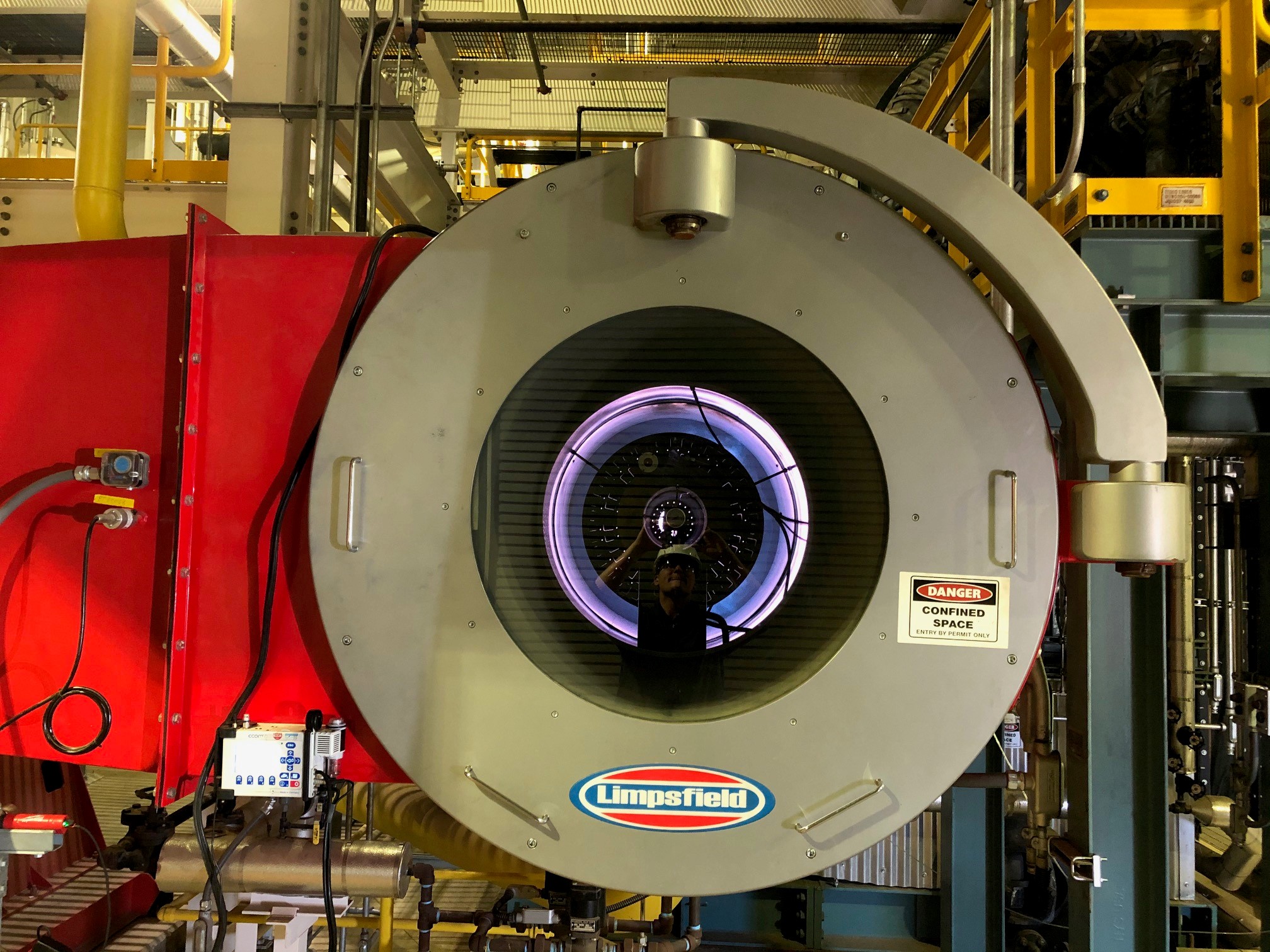

Soot Build Up Inside A Watertube Boiler

Tuning your boiler is essential to ensure that the combustion process is optimized for efficiency, safety, and emissions. A poorly tuned boiler can result in a range of problems, including increased fuel consumption, higher emissions, reduced performance, and safety hazards. Regular combustion tuning is necessary for both hot water and steam boilers.

The air to fuel ratio is a key indicator of performance in burner. With too little air, unburned fuel (which forms soot) will get deposited in the boiler. This causes all sorts of problems with heat transfer and efficiency. If there is insufficient fuel the unit is not able to meet demand. Ensuring this ratio is in balance is the key to an efficient system.

How Frequently Should You Tune A Boiler?

It is a best practice to perform combustion tuning twice a year, in the spring and the fall. This is because changes in temperature affects air density and the air-to-fuel ratio. We generally see issues in combustion arise after a 15 – 20 degree temperature change.

Factors That Affect Boiler Combustion

Several factors can affect the combustion process, including:

Environmental Changes: Changes in ambient temperature, humidity, and air pressure can affect the combustion process, requiring adjustments to maintain optimal performance.

Building Layout: Changes in the building layout, such as expansions or modifications, can affect the steam system’s demands, requiring adjustments to maintain optimal performance.

Wear and Tear: Over time, boilers can experience wear and tear, leading to a decline in performance. Regular tuning can help compensate for these issues, maintaining optimal performance.

Steps to Tune Your Boiler

IMPORTANT NOTE: Boiler tuning should always be done by a professional company.

When performing a combustion tune, it is essential to warm up the boiler correctly and tune the boiler through the complete firing cycle. Below we will discuss a sophisticated electronic meter known as a combustion analyzer. This tool analyzes gas percentages present in the exhaust to determine the ideal mixture.

Here are the general steps for tuning a boiler:

- Inspection: Begin by inspecting the entire system, including the fuel lines, combustion chamber, and exhaust vents. Look for any signs of corrosion, leaks, or blockages, and repair or replace any damaged parts.

- Combustion Analysis: To determine the combustion performance, take combustion measurements using a combustion analyzer, including oxygen levels, carbon dioxide levels, and stack temperature.

- Adjusting Air and Fuel Settings: Adjust the air and fuel settings on the burner control panel until you optimize the air-to-fuel ratio. Complete this by adjusting the air damper, fuel pressure, and combustion air flow. The ideal air-to-fuel ratio depends on the type of fuel and the boiler’s design.

- Testing: It is important to test the boiler to ensure it is functioning correctly. This can be done using a flue gas analyzer to measure the carbon monoxide (CO) levels to determine efficiency.

Additional Tuning Considerations

Never perform Boiler tuning solely by sight and sound. You must use a combustion analyzer for a successful tune. Additionally, having burner manufacturers’ data on hand for a technician is helpful. This allows them to verify design set points, such as nozzle pressure, manifold pressure, and gas supply.

Another important consideration is if you are tuning a duel-fuel or single fuel burner. When you are tuning a dual-fuel burner, such as a gas/oil combination burner, you must tune each independently.

Safety Considerations

When tuning a boiler, safety should always be a top priority. Here are some key safety considerations to take into account:

- Proper equipment and tools: Technicians performing boiler tuning should always have the proper equipment and tools to do the job safely. This includes personal protective equipment (PPE), such as gloves, safety glasses, and respirators, as well as specialized tuning equipment like combustion analyzers.

- Fire hazards: Combustion tuning involves working with high temperatures and combustible materials. Proper fire prevention measures, such as fire extinguishers and fire suppression systems, should be in place and accessible in case of an emergency.

- Training and experience: Boiler tuning should only be performed by trained and experienced professionals. They understand the risks involved and know how to perform the work safely. Improper tuning can result in serious injury or even death, as well as damage to the boiler or surrounding equipment.

Boiler Tuning Conclusion

Tuning your boiler is a crucial aspect of boiler maintenance, ensuring optimal performance, efficiency, and safety. By following the steps outlined in this article, you can maintain your boiler’s optimal performance, minimize emissions, and extend its lifespan. Regular maintenance and tuning are essential to ensure optimal boiler performance and prevent safety hazards.