MECHANICAL CONTRACTOR

Experts In Installation, Maintenance and Repair

THE MECHANICAL EXPERTS

For over 55 years we have been the leader in installing, maintaining and servicing mechanical equipment. With 7 locations, and over 200 employees, Rasmussen Mechanical has wide-ranging expertise in commercial and industrial equipment.

24/7 Number: 1-800-237-3141

Email: sales@rasmech.com

Office Locations: Denver CO, Omaha, NE, Sioux City, IA, Sturgis, SD, Gibbon, NE, Council Bluffs, IA

Office Hours – Monday – Friday: 7:00am – 4:00pm

EQUIPMENT WE WORK ON

|

|

SERVING THE MIDWEST FOR OVER 55 YEARS

Our team of factory-trained experts understand the intricacies of engineering and service work. With 11 different department we are sure to be able to tackle all of your mechanical needs. From boilers to burners, to HVAC systems, Air compressors and more. We have the know how to get the job done right the first time. We can provide timely and professional guidance both to you and your company. See the Rasmussen Mechanical Services difference:

24/7 Emergency Services Available and Technical Support

Dedicated Project Managers

Responsive, Reliable Communication

HOW CAN WE HELP?

Check Out SOME OF Our Recent Projects

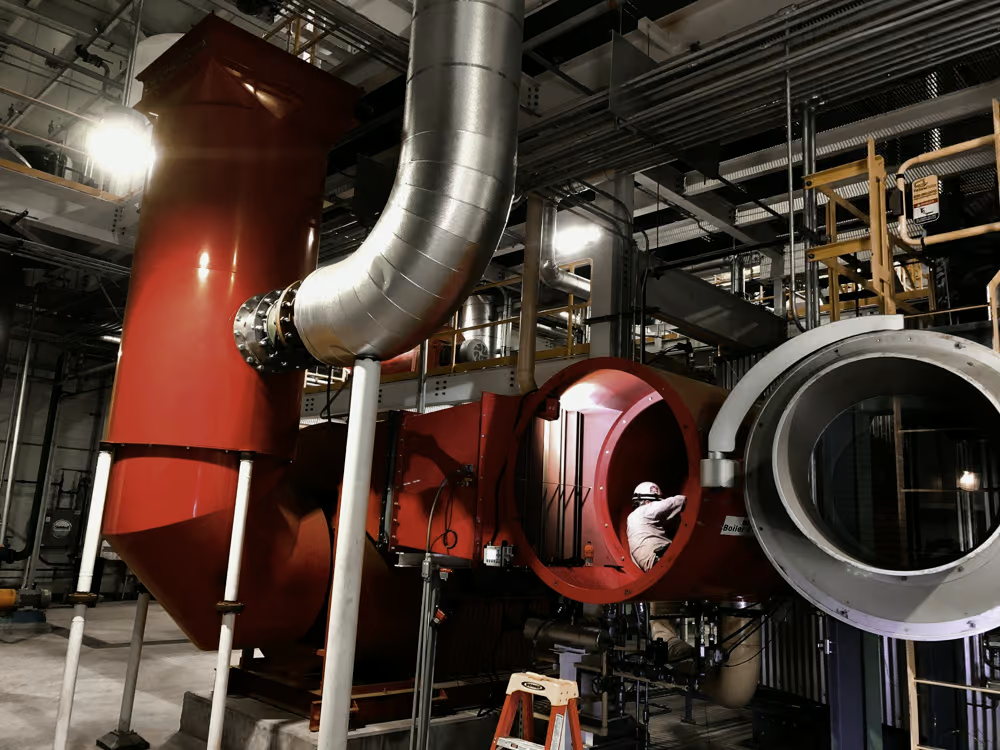

COMPLETE BOILER RETUBE

RMS removed 484 existing tubes and the rear tube sheet from a boiler at a global food corporation. The burner and refractory were also removed. For an increase in efficiency, rifled (XID) tubes were installed mechanically and sealed by welds. A new burner cone and block refractory were also installed.

Upon completion of the boiler repairs, the unit was boiled out and the burner was tuned for efficiency.

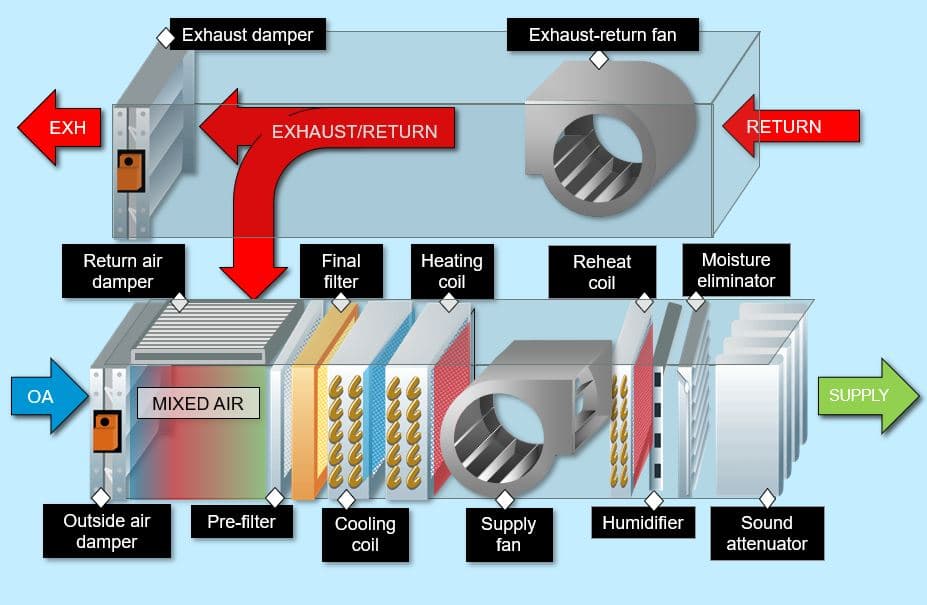

HVAC SYSTEM REDESIGN AND INSTALL

RMS was contracted to renovate a retail facility that was built in 1906 and convert it into The Hotel Sturgis. This required a complete HVAC re-design for the 22-room facility, as well as for the coffee shop and lobby. Old dilapidated equipment was removed and replaced with ultra-high efficiency equipment. We installed exhaust systems for bathrooms as well as venting for dryers. Design, sheet metal, HVAC, and ventilation services were all used during this project.

Safety practices played a BIG role in preventing injury on a site that was dangerous at points due to the age of the structure. The building went from 80% efficient equipment to 95+% efficient equipment upon project completion.

INDUSTRIAL BOILER TUNING

Rasmussen Mechanical’s burner technicians tuning a massive duel fuel Limpsfield burner.(Natural Gas and Fuel Oil as back-up)

This burner is attached to a 3,600 BHP Cleaver Brooks boiler with Autoflame controls we installed three years prior.

As part of that project, we upgraded controls on an existing boiler. We also installed a stack economizer on the new system to assist in energy reduction. An MAU was also installed to provide tempered combustion air when the ambient temperature is below 45 de.grees F.

DUCTING AND MUA INSTALLS

RMS was contracted to install 2 new make-up air units along with ducting to help balance out humidity levels in this facility. Weather was a big factor and the team had to deal with high winds, rain and ice at times. Rasmussen Mechanical worked hand in hand with the scaffolding company that would sometimes require daily modifications. The project was completed with no injuries and in about 4 months on the job site.

Check Out More Of Our Projects Here

CHECK OUT OUR MECHANICAL CONTRACTOR BLOG

15 BOILER SPARE PARTS YOU SHOULD HAVE ON HAND

Having spare parts for your boiler’s mission critical components is a great way to save on downtime when something fails

HOW TO IMPROVE YOUR INDUSTRIAL MAINTENANCE PROGRAM

Every year brings new challenges and nobody knows that better than facility managers. Facility managers need to do everything they can to ensure their facility…

5 STEPS TO KEEP YOUR HVAC SYSTEM RUNNING THROUGH THE HEAT

The Heat Is Here! Which means your HVAC system is working hard, to keep your building cool.

THE SIGNIFICANCE OF A SYSTEMATIC INDUSTRIAL SHUTDOWN

Industrial shutdowns are one of the most impactful events in the routine operation of your plant.

AIR HANDLING UNIT MAINTENANCE THAT GETS RESULTS

Routine AHU cleaning extends the life of equipment and reduces operating costs. Check out our maintenance checklist to keep your equipment running efficiently.