Boiler Maintenance – Everything You Need to Know

Understanding Boiler Efficiency

Before we get into boiler maintenance, lets talk efficiency. Boilers draw in the fresh air, heat it, and send it out the stack. Optimal conditions would generate the smallest amount of flue gas (exhaust gas that’s expelled) at the lowest possible temperature.

The boiler system takes in cold water, heats it to steam, and uses the heat.

One of the easiest ways for a business to reduce operating expenses is to use energy-efficient equipment. Here are a few quick tips to help make your boiler system more efficient and save money on your monthly bills:

- Install an economizer.

- Install a variable frequency drive.

- Preheat combustion air.

- Return condensate to the boiler.

- Control blowdown rate.

- Survey steam traps.

- Tune your burner regularly for seasonal changes

- Outdoor temperature reset and night set back (hydronic boilers)

Want more information and additional tips? Check out the full list here.

How does boiler feedwater quality affect the operation of my boiler?

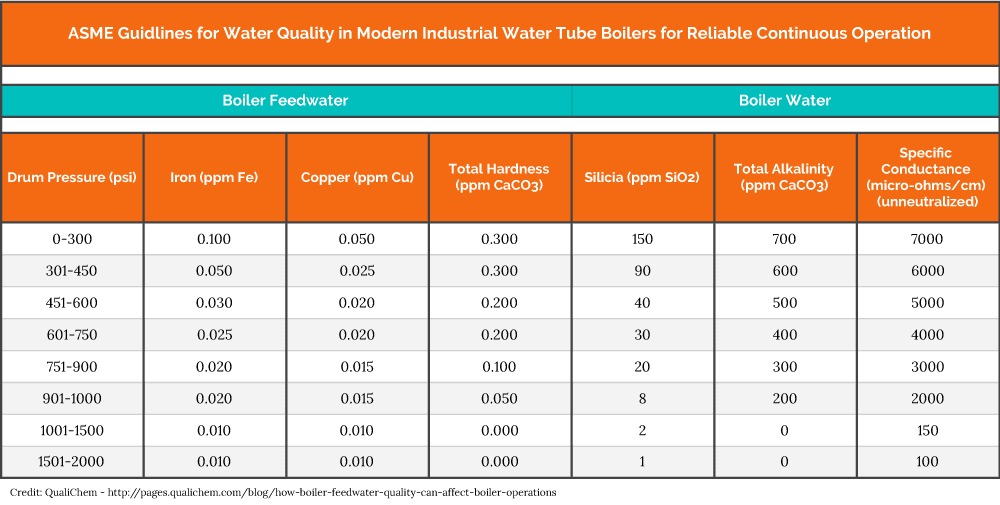

Low-quality boiler feedwater contains impurities and gases that can lead to reduced efficiency and boiler or system leaks. Pure water is neutral in taste, odor, and color. While this is ideal for transporting energy due to its convenient boiling point and steam generation, it’s expensive to generate. You are likely to find suspended and dissolved solids, as well as dissolved gases, in well and municipal water. Feedwater can also contain industrial wastes, sediment, and microorganisms.

Poor water treatment can affect your boiler operations in numerous ways:

- Dissolved oxygen can cause oxygen pitting and leaks.

- Dissolved CO2 traveling out of the boiler with the steam could make condensate acidic. This acid condensate will corrode away your steam pipe while also adding iron to your boiler water.

- Dissolved solids can cause scale to form in feedwater pipes, economizers, and boilers. This scale prevents boiler water from cooling metal heat-absorbing surfaces. As the problem worsens, the boiler can develop tube roll leaks, hot spots, and eventually a pressure part failure.

- A high concentration of usual boiler impurities, over-treatment with chemicals, or an accidental introduction of organic matter (grease or oil) leads to foaming carry-over. This pushes the foam out the boiler steam outlet and can have serious consequences. Water hammer in a steam line, erosion in steam piping and boiler low water events are all possible when this occurs.

Read this article for more information on how feedwater can impact your boiler.

How can I prevent these issues?

The most effective and lowest cost water treatment program pretreats, deaerates and chemically treats the raw water

- Dissolved gases detach from feedwater in the deaerator or hot water tank. Careful attention is required to ensure that gases safely separate from the boiler water before feeding the boiler. Good practice would be to record the feedwater temperature in your boiler logbook during every operator round. Follow with a suitable chemical treatment program to remove or treat the remaining trace amounts of dissolved gas.

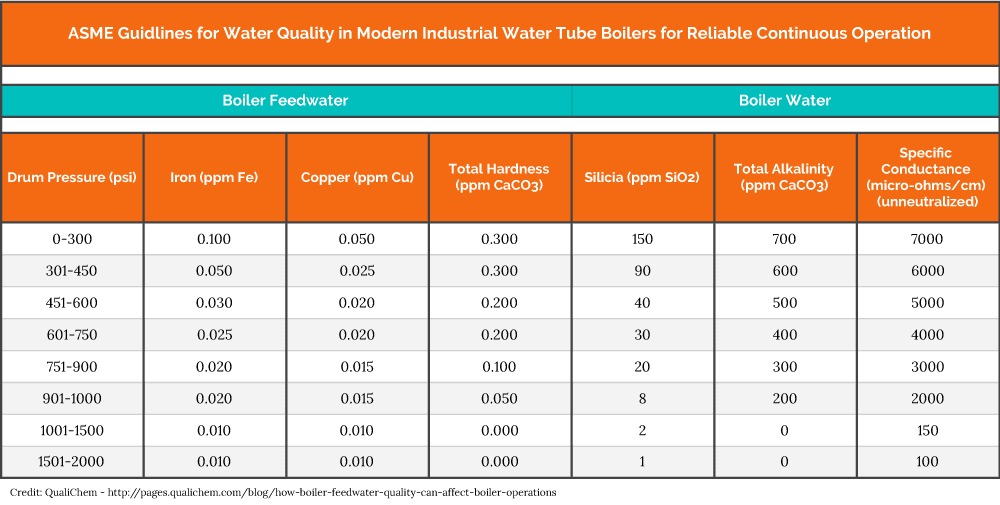

- Dissolved solids, depending on the nature of the impurity, can be removed by a water softener and a Reverse Osmosis (RO) System. Make it a habit to record the makeup water conductivity, feedwater conductivity, and boiler water conductivity in your boiler logbook during every operation.

If carry-over or foaming occurs and boiler water conductivity is within range, call your water treatment company. Tests will determine if you can alleviate foaming with a simple water additive. Also, it can identify if the boiler will need to be brought offline and cleaned by a qualified service company to remove contamination.

When should I contact a service company?

- When feedwater temperatures drop below its recommended temperatures. (190 F for hot water tanks or 225 F for Deaerators)

- When the feedwater conductivity is above the recommendation of your water treatment company.

- When the boiler water conductivity is above the recommendation of your water treatment company, and blowdown does not get conductivity within range.

- If carry-over is caused ‘mechanically’ or by the way the boiler is being loaded.

Reasons to service your boiler annually

Boiler preventative maintenance will help you steer clear of breakdowns and costly expenses. It will also help increase the longevity of your system while maintaining the safety of your business and employees. Here are additional specific reasons to keep up with your boiler service schedule:

- Save on Boiler Repairs – Regular boiler maintenance keeps your repair costs down by catching problems early before they become costly.

- Save Lives – Safety tests performed during regular service appointments can prevent deaths from carbon monoxide poisoning and other dangerous boiler operating scenarios.

- Ensures Insurance Coverage and Staying Under Warranty – Most boiler warranties and insurance policies require annual servicing to provide coverage.

- Catch Problems Early – Identify any problems and address them before any significant damage occurs. You want to avoid expensive repairs and possible replacement of your boiler system.

Routine boiler maintenance

Daily Maintenance

- Check water level gauge glass, record the pressure gauge and temperature gauges

- Check LWCO and ALWCO operation and ensure the burner shuts down

- Blowdown the water column and gauge glass

- Turn off burner control switch, observe the response to flame failure

- Observe operating control and high limit control

- Perform bottom blowdown to remove sludge and sediment.

- Observer burner refractory cone, looking for broken chunks or hot spots

Weekly Maintenance

- Check all linkages on burner controls and the automatic draft controllers

- Check air damper on the burner

- Test valve operation in gas train

- Check pilot and igniter, look at the condition of the flame

- Check process of LWCO – blowdown boiler water level through the drain. Watch gauge glass to see burner cut off before losing sight of water.

Monthly Maintenance

- Test limit controls on boiler.

- Test flame detection controls.

- Check blowdown for sludging at bottom of boiler.

- Verify blowdown separator and cooler operation.

- Check floor drains for proper function.

- Check boiler fresh air inlet screens.

Annual Maintenance

- Disassemble and check LWCO and ALWCO for sludge, corrosion or electrical switch defects.

- Verify and tune up burners and settings. **We recommend quarterly tuning by a qualified technician**

- Inspect fire side for soot or damage and water side for scale or corrosion & Clean the boiler inside and out.

- Hydro test boiler for leaks (tube joints and piping).

- Inspect all refractory for fallen broken chunks.

- Check gas regulator pressure settings.

- Replace or re-certify safety valves.

- Bubble test fuel train safety shut-off valves.

Download Our Printable Boiler Maintenance Checklist Here

The importance of boiler logs

To keep any facility up and running, managers and operators must know the machinery they work with daily. Designing a process that prioritizes transparency reduces boiler accidents and increases the lifetime of your equipment.

Boiler logs tend to land under two categories: daily operational logs and maintenance activity logs. Each boiler in the facility should have a separate log sheet. These should have room for two sets of readings a day at a minimum. Consider two sets of readings per shift if running continuously. Be sure to also include weekly and monthly checks. A comments section for notes on irregularities or potential significant events for other operators to act on is recommended.

Boiler logs are a standard in maintaining your machinery. Records should be updated daily with specific, useful information. It’s critical to stick to a schedule. Boilers can create fireside or waterside scale build-up, which can force an emergency shutdown.

Management should inspect boiler logs and spot check readings to prevent ‘pencil whipping.’ If the data in the log is not accurate, it can lead to poor water treatment and maintenance decisions.

WHAT SHOULD BE IN MY LOGS?

GENERAL

- Air compressor, control pressure (PSIG)

- Outdoor air temperature (degrees F)

- City water supply pressure (PSIG)

BOILER

- Boiler(s) in service

- Fuel in use

- Operating time (hours)

- Operating cycles(number)

- Amount of fuel on hand

- Boiler water level (normal, low, high)

- Firing level (rate)

- Flame condition (observed)

- Boiler pressure (PSIG)

- Boiler water temperature, hot water (degrees F)

- Stack temperature, net (degrees F)

GAS FUEL

- Pilot gas pressure (inches WC)

- Burner gas pressure (ounces/square inch or PSIG)

- Gas used (cubic feet)

OIL FUEL

- Oil pump in service

- Vacuum at oil pump (inches Hg)

- Oil pressure at pump (PSIG)

- Atomizing medium pressure, air, steam (PSIG)

- Oil pressure at burner and regulating valve (PSIG)

CONDENSATE SYSTEM (STEAM BOILERS)

- Boiler feed pump in service

- Condensate return temperature (degrees F)

- Water level in condensate tank (normal, low, high)

- Make up water rate (gallons)

FORCED HOT WATER CIRCULATION SYSTEM

- Circulating pumps in service

- Return water temperature (degrees F)

- Water level in expansion tank (normal, high, low)

BOILER WATER TREATMENT

- Level of chemicals in treatment tank

- Treatment pump in service (low, normal)

- Boiler water sample taken

MAINTENANCE OR REPAIR OPERATIONS

- Record these operations in the log sheets

Who is responsible for boiler logs?

From the ASME National Board, the breakdown of responsibility for your boiler logs is as follows:

- Operator – Responsible for taking boiler readings, ensuring accuracy, and initial analysis.

- Management – Responsible for implementing a log program and supervising its continuous completion. Also, responsible for ensuring that an analysis program is carried out.

- All Involved Parties – Responsible for the retention of logs in accordance with the facility policy. They also must examine records to determine trends and recommend action in response to these trends.

The Cost Savings Of Preventative Boiler Maintenance

Preventative boiler maintenance will save you money by preventing:

- Fuel Overuse – If your equipment isn’t performing at its best, it will burn more fuel, driving up your bills.

- Minor Problems Becoming Major Problems If routine maintenance isn’t performed, this can lead to costly repairs or in some cases, a complete replacement.

- Outages – When outages occur due to delayed maintenance, your organization will likely lose revenue.

- Safety Hazards – Routine maintenance can reduce the risk of fire, pressure explosion, and carbon monoxide buildup by ensuring devices are clean and adequately ventilated.

Contingency Planning

Contingency planning will save you from drowning in repair costs or hemorrhaging revenue due to a facility shutdown. A contingency plan should follow these necessary steps:

- Review Your Insurance Policy – Make sure you’re fully covered, and your system is good to go in case of emergencies. If you aren’t sure, check with your insurance agent and your mechanical service provider.

- Get Familiar with Your Machinery – Keep up with your boiler logs. Conduct preliminary tests to ensure your boiler system is switched on and functioning before you need it.

- Have a Backup Handy – Nobody expects the worst to happen. When it does and your business needs a boiler, you want to make sure you’re covered. At Rasmussen Mechanical Services, we offer rental boilers along with 24-hour emergency service so that you never have to wait for a solution.

Boiler services

Rasmussen Mechanical Services’ Boiler Repair and Code Services Division focus on delivering swift, quality services and repairs for our customers. We hold R, S, H, U, and PP stamps, and are equipped to perform a full array of ASME Code Services and NBIC repairs.